Top 5 Benefits of Using Non Return Valves for Efficient Fluid Control

In the realm of fluid control, the efficiency and reliability of systems hinge significantly on the components that govern flow direction and pressure regulation. Among these, the Non Return Valve stands out as a critical device, ensuring that fluid flows in a single direction while preventing backflow that can lead to inefficiencies or system failures. According to industry expert Dr. Emily Hartman, a prominent engineer in valve technology, “The implementation of Non Return Valves can dramatically enhance system performance and longevity, safeguarding equipment from the damaging effects of reverse flow.”

As industries progressively adopt advanced fluid management strategies, understanding the top benefits of Non Return Valves becomes essential for engineers and decision-makers. These valves not only optimize flow management but also protect against potential failures, reduce maintenance costs, and improve overall operational efficiency. Dr. Hartman suggests that "by integrating high-quality Non Return Valves into fluid systems, businesses can achieve substantial cost savings and minimize downtime." The subsequent exploration of the top five benefits will provide valuable insights into how these components can transform fluid control systems, leading to smarter, more efficient applications across various sectors.

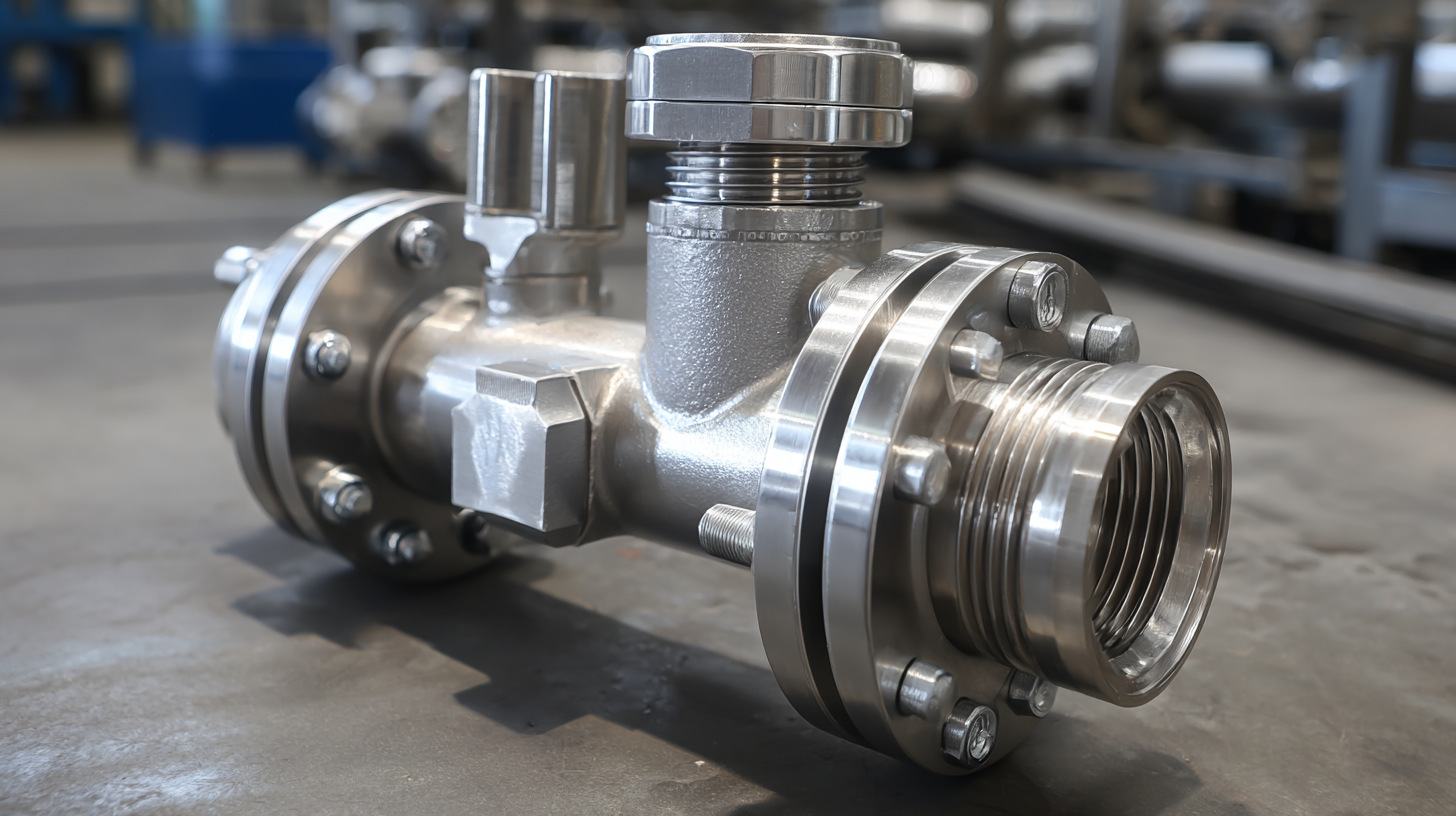

Understanding Non Return Valves: A Key Component in Fluid Systems

Non-return valves, also known as check valves, play a crucial role in fluid control systems by ensuring unidirectional flow and preventing backflow. These valves are designed to allow fluid to pass in one direction while effectively blocking it from returning. This characteristic is essential in various applications, ranging from water supply systems to industrial processes, as it helps maintain system pressure and protects pumps and other components from potential damage caused by backflow.

In fluid systems, the use of non-return valves contributes significantly to efficiency and reliability. By preventing reverse flow, these valves minimize the risk of contamination and ensure that the fluids remain clean and uncontaminated. Additionally, non-return valves contribute to energy savings by reducing the need for extensive pumping systems, as they help maintain consistent flow rates and pressure levels throughout the system. Overall, understanding the function and benefits of non-return valves is vital for anyone involved in fluid management, as they are key components that enhance performance and longevity in fluid control applications.

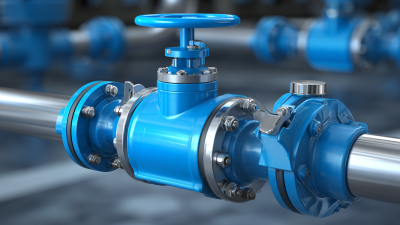

Advantages of Non Return Valves in Preventing Backflow and Contamination

Non-return valves, also known as check valves, play a pivotal role in efficient fluid control, especially in preventing backflow and contamination. According to a recent report by MarketsandMarkets, the global check valve market is expected to reach $5.2 billion by 2025, indicating a growing recognition of their importance in various industries, including water treatment, oil and gas, and chemical manufacturing. By allowing fluid to flow in only one direction, these valves effectively eliminate the risk of reverse flow, thereby safeguarding the integrity of the system against potential contamination.

When implementing non-return valves, it's crucial to consider their placement within the system. A well-placed check valve can enhance efficiency and prolong the lifespan of other equipment by preventing damage caused by backflow. For optimal performance, experts recommend regularly inspecting these valves and ensuring they are free from debris, as dirt and sediment can hinder their functionality. Additionally, using high-quality materials can improve resilience against harsh operating conditions, thereby reducing maintenance costs over time.

Tip: Always choose a non-return valve that is compatible with the specific fluid type and pressure requirements of your application to ensure maximum effectiveness and safety. This simple step can significantly reduce the risk of failure and enhance operational efficiency.

Enhanced System Efficiency: How Non Return Valves Optimize Fluid Control

Non-return valves, essential components in fluid control systems, significantly enhance system efficiency by preventing backflow and ensuring smooth fluid flow in one direction. According to a recent report by the Fluid Control Association, implementing non-return valves can reduce energy loss by up to 30% in various applications, such as water treatment and chemical processing. This optimization allows for more efficient operation of pumps and compressors, effectively maximizing their output while minimizing operational costs.

Further supporting their impact on efficiency, research from the International Journal of Fluid Mechanics reveals that systems equipped with non-return valves experience a decrease in maintenance frequency. By preventing reverse flow, these valves protect sensitive equipment from potential damage and wear, thus extending the lifespan of the entire system. Consequently, companies can save on both repair costs and downtime, resulting in increased reliability and productivity in their operations. The integration of non-return valves stands as a key strategy for industries aiming to enhance their fluid control efficiency while ensuring sustainable practices.

Durability and Maintenance Benefits of Non Return Valves in Various Applications

Non-return valves, also known as check valves, are essential components in various fluid control systems due to their durability and low maintenance requirements. With their robust design, these valves can withstand harsh environmental conditions and high-pressure scenarios, making them suitable for a wide range of applications, from industrial processes to municipal water systems. The materials used in their construction, such as stainless steel or reinforced plastics, provide enhanced resistance to corrosion and wear, contributing to the longevity of the system.

Moreover, the maintenance benefits of non-return valves cannot be overstated. Their simple design means fewer moving parts, which reduces the likelihood of mechanical failure. This simplicity leads to less frequent maintenance interventions, saving time and reducing operational costs. In many cases, non-return valves are designed to work effectively without the need for external assistance, enabling them to operate with minimal oversight. This reliability ensures consistent fluid flow and minimizes the risk of backflow, further enhancing system efficiency across diverse applications.

Cost-Effectiveness: Long-Term Savings with Non Return Valves in Fluid Management

Non-return valves, also known as check valves, play a pivotal role in enhancing fluid control systems. One of the primary advantages of using these valves is their cost-effectiveness in fluid management. By preventing backflow, non-return valves protect equipment from damage and reduce the need for frequent repairs or replacements. This protection translates to significant long-term savings, allowing businesses to allocate resources more efficiently.

Implementing non-return valves not only fosters operational consistency but also streamlines maintenance processes. By minimizing fluid leaks and loss, these valves contribute to reduced waste, thus lowering overall operating costs. Companies can enhance their bottom line by integrating these essential components into their fluid control strategies.

**Tips:** When selecting non-return valves, consider the material compatibility with your fluids to ensure optimal performance. Regularly inspect these valves for any signs of wear or malfunction to maintain their efficiency. Additionally, educate your team on the benefits and proper maintenance of non-return valves to maximize their effectiveness in your fluid management systems.

Top 5 Benefits of Using Non Return Valves for Efficient Fluid Control

This chart illustrates the cost-effectiveness of using non return valves in fluid management, highlighting the long-term savings associated with their implementation across various industries.

Related Posts

-

The Essential Role of Non Return Valves in Preventing Backflow in Industrial Systems

-

Challenges with Using Best Non Return Valves in Industrial Applications

-

Exploring Market Opportunities for Non Return Valves at the Successful 137th Canton Fair

-

How to Choose the Right Double Check Valve for Your Application

-

Understanding Global Manufacturing Standards for the Best Double Check Valve Selection Guide

-

7 Best Prv Valve Choices to Enhance Your System Efficiency