How to Choose the Best Wafer Check Valve for Your Industrial Needs

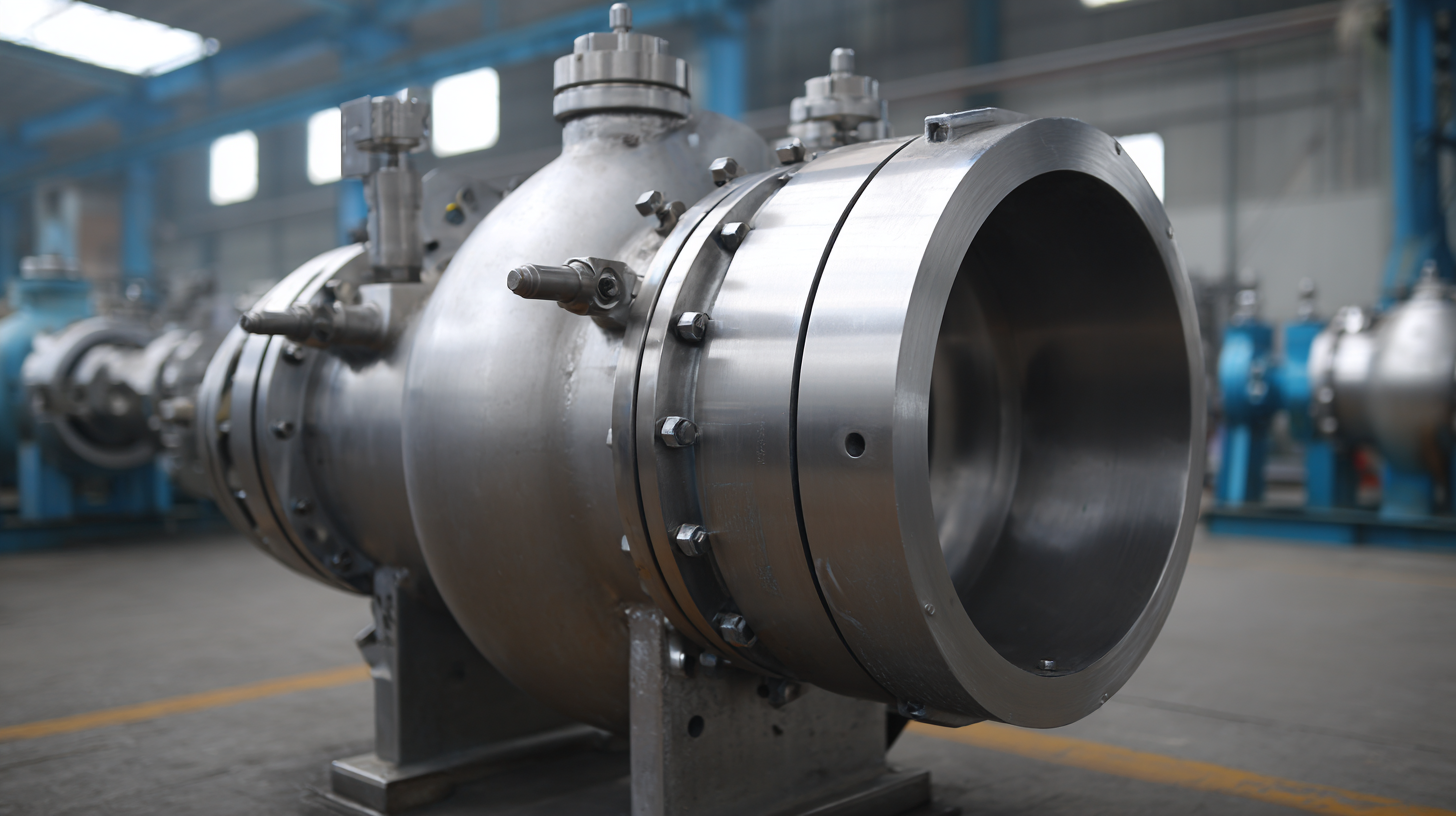

When it comes to industrial applications, the efficiency and reliability of fluid control systems are paramount. One essential component that plays a critical role in these systems is the Wafer Check Valve. This device not only prevents backflow but also ensures optimal performance under varying pressure conditions. Choosing the best Wafer Check Valve for your specific needs can significantly impact the efficacy of your operations. In this blog, we will explore the various benefits of different types of Wafer Check Valves, examining their material options, design features, and functionalities.

When it comes to industrial applications, the efficiency and reliability of fluid control systems are paramount. One essential component that plays a critical role in these systems is the Wafer Check Valve. This device not only prevents backflow but also ensures optimal performance under varying pressure conditions. Choosing the best Wafer Check Valve for your specific needs can significantly impact the efficacy of your operations. In this blog, we will explore the various benefits of different types of Wafer Check Valves, examining their material options, design features, and functionalities.

By understanding these aspects, you can make an informed decision that aligns with your industrial requirements, ensuring seamless and safe fluid flow management in your processes.

Key Factors to Consider When Selecting Wafer Check Valves for Industrial Applications

When selecting wafer check valves for industrial applications, various key factors must be considered to ensure optimal performance. One critical aspect is the growing market for check valves, which is projected to expand from $4.57 billion in 2024 to $6.5 billion by 2035. This substantial growth indicates a rising demand for reliable and efficient fluid control solutions across various industries, including oil, gas, and wastewater management.

Another important factor is the integration of modern technologies in valve design. With increasing automation trends and the demand for enhanced operational efficiency, industries are leaning towards advanced valve technologies that facilitate seamless integration into existing systems. Reports indicate that sectors such as oil and gas are witnessing significant investments aimed at improving exploration and production activities, further driving the need for high-quality wafer check valves. As the market evolves, understanding these dynamics is essential for making informed decisions about valve selection to meet specific industrial requirements.

How to Choose the Best Wafer Check Valve for Your Industrial Needs

| Criteria | Details | Importance Level |

|---|---|---|

| Material Compatibility | Ensure the valve material is compatible with the fluid being transported. | High |

| Pressure Rating | Select valves that can withstand the maximum operating pressure of your system. | High |

| Size and Connection Type | Choose the correct size and connection type to fit your pipeline. | Medium |

| Flow Direction | Ensure the valve allows for the correct flow direction as required. | High |

| Operating Temperature | Valves must be suitable for the temperature range of the application. | Medium |

| Maintenance Requirements | Consider the ease of maintenance and availability of spare parts. | Medium |

| Cost | Assess the total cost vs. budget and long-term value. | Low |

Emerging Technologies Shaping the Future of Wafer Check Valves by 2025

The wafer check valve market is poised for significant evolution by 2025, driven by emerging technologies that enhance performance and efficiency in industrial applications. According to a recent market research report, the valve industry is expected to grow at a CAGR of around 5.6% over the next few years, with an increasing focus on automation and smart technologies leading the charge. Innovations such as IoT-enabled monitoring systems are making it easier to track valve performance in real-time, thus reducing maintenance costs and improving system reliability.

Additionally, materials science advancements are reshaping the design and functionality of wafer check valves. The development of corrosion-resistant and lightweight materials is projected to enhance valve longevity and operational efficiency. A report from the Valve Manufacturers Association indicates that manufacturers adopting these new materials can expect an up to 25% increase in valve lifespan, significantly impacting the total cost of ownership for industrial operations. As these technologies continue to emerge, stakeholders must stay informed and adaptable to select the best wafer check valves that meet their specific industrial needs.

Alternative Valve Solutions: When to Consider Options Beyond Wafer Check Valves

When working in industrial applications, while wafer check valves are a popular choice due to their compact design and low pressure drop factors, there are scenarios where alternative valve solutions may be more appropriate. For example, a report by the Global Market Insights indicates that the valve market is expected to reach USD 80 billion by 2026, driven by the need for more efficient systems in oil and gas, water treatment, and power generation sectors. In cases where the fluid medium is aggressive or where frequent cycling is required, alternative valves such as swing check valves or ball check valves can provide superior performance and reliability.

Moreover, using innovative designs such as automated control valves could also offer significant advantages. A study by Frost & Sullivan highlighted that automation in valve systems could reduce operational costs by up to 30%. This is critical for industries aiming to enhance their operational efficiency. Therefore, while wafer check valves serve a reliable function, businesses must evaluate their specific operational conditions and consider alternatives that align better with their performance requirements and budget constraints to ensure optimal productivity and cost-effectiveness.

Comparative Analysis of Check Valve Types for Industrial Applications

Understanding Material Selection for Optimal Performance of Wafer Check Valves

When selecting a wafer check valve for industrial applications, understanding material selection is crucial for ensuring optimal performance. Wafer check valves are commonly constructed from various materials including stainless steel, ductile iron, and plastic, each offering distinct benefits suited for specific environments. According to a report by Markets and Markets, the global valve market is projected to reach $86.6 billion by 2027, emphasizing the growing importance of material performance in industrial settings.

Stainless steel is favored for its strength and corrosion resistance, making it ideal for high-temperature and high-pressure applications. A study by the American Society of Mechanical Engineers noted that valves made from stainless steel can withstand temperatures up to 450°F, thereby enhancing their longevity in demanding conditions. On the other hand, ductile iron provides excellent mechanical properties and is more cost-effective for lower pressure applications. Additionally, plastic options like PVC or CPVC are increasingly used in chemical processing due to their lightweight and resistance to corrosive agents, proving essential for industries that require versatility and durability.

Selecting the ideal material not only impacts performance but also influences the overall lifecycle costs of maintaining the valve. According to the Valve Manufacturers Association, improper material selection can lead to significant operational disruptions and increased maintenance costs, underlining the necessity for careful consideration in the design phase to ensure efficiency and reliability in industrial systems.

Future Trends in Industrial Fluid Dynamics and Their Impact on Valve Selection

As the landscape of industrial fluid dynamics evolves, so too does the necessity for advanced valve solutions that can adapt to changing operational demands. Recent reports highlight that the global valves market is projected to reach $76 billion by 2025, driven largely by automation and the integration of smart technologies across various industries. The ability of wafer check valves to accommodate these innovations, particularly in sectors like oil and gas, has positioned them at the forefront of valve selection processes.

Furthermore, sustainability goals are reshaping fluid management strategies, giving rise to eco-friendly materials and energy-efficient designs in valve manufacturing. A study conducted by the Market Research Future indicates a compound annual growth rate (CAGR) of 5.4% in the demand for sustainable fluid control solutions from 2021 to 2028. These trends emphasize the importance of selecting wafer check valves that not only meet current regulatory standards but are also compatible with evolving technologies in fluid dynamics, ensuring businesses remain agile and compliant in a rapidly changing industrial environment.