Why Choose Die Casting Molds for Your Manufacturing Needs?

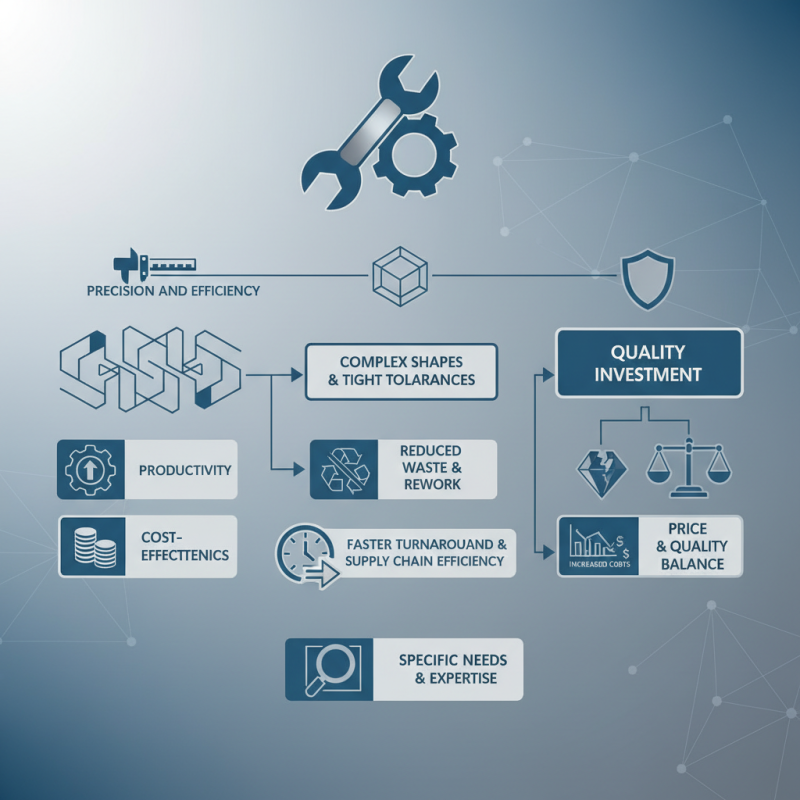

In today's competitive manufacturing landscape, choosing the right production method is crucial. Die Casting Molds have emerged as a preferred option for many businesses. They offer precision and efficiency, driving productivity and cost-effectiveness.

Die Casting Molds can produce complex shapes with tight tolerances. This capability reduces waste and minimizes rework. Companies often see faster turnaround times, improving their overall supply chain efficiency. However, some manufacturers might overlook the importance of selecting the right mold material. This can lead to issues with durability and performance.

Investing in quality Die Casting Molds is essential for success. A poorly-designed mold may result in defects and increased costs. It's vital to balance price and quality when making this choice. Manufacturers should reflect on their specific needs and the expertise required to utilize these molds effectively.

Benefits of Die Casting Molds in Manufacturing Processes

Die casting molds offer significant advantages in manufacturing. These molds lead to high precision and excellent surface quality in produced parts. According to a recent industry report, die casting can achieve dimensional tolerances of ±0.005 inches. This precision is crucial for industries like automotive and aerospace, where even small discrepancies can cause substantial failures.

The speed of the die casting process is another benefit. Parts can be produced in large volumes within a short time frame. In fact, die casting can reduce cycle times by up to 30% compared to other methods. This efficiency not only boosts productivity but also lowers manufacturing costs, giving businesses a competitive edge.

Tips: When considering die casting molds, always assess the material compatibility. Certain alloys work better than others, impacting the final product. Additionally, ensure that the mold design allows for proper cooling. Poor cooling can lead to defects. Take time to review these factors; they are essential for success in this manufacturing technique. Investing in quality molds pays off in reliable products and satisfied customers.

Why Choose Die Casting Molds for Your Manufacturing Needs?

| Benefit | Description | Applications |

|---|---|---|

| High Precision | Die casting molds provide excellent dimensional accuracy and surface finish for complex designs. | Automotive parts, electronics housings |

| Efficiency | Rapid production rates lead to lower manufacturing costs and shorter lead times. | Mass production of metal components |

| Material Variety | A wide range of alloys can be used, including aluminum, zinc, and magnesium. | Consumer goods, aerospace components |

| Reduced Waste | Die casting generates less scrap material compared to other manufacturing methods. | Industrial machinery parts |

| Strength and Durability | Components produced by die casting offer high strength and reliability for demanding applications. | Construction equipment, tooling |

Overview of Die Casting Techniques and Applications

Die casting is a popular manufacturing technique that offers various applications. This process involves forcing molten metal into a mold under high pressure. The result is precise components that are durable and have a smooth finish. Many industries use die casting for parts like engine blocks and housings.

One notable advantage is the speed of production. Die casting allows for high-volume output in a short time. However, this speed may lead to overlooked details in the design phase. It's essential to consider that while creating complex shapes, some may not meet the desired quality standards. Reflection on the initial design can prevent costly revisions.

In terms of materials, aluminum and zinc are commonly used in die casting. Both materials offer unique benefits. Yet, the choice of metal can impact the final product's performance in ways that can be challenging to assess at first. It's vital to understand these intricacies to ensure the completed parts meet industry needs without unexpected issues.

Materials Used in Die Casting Molds: A Comprehensive Guide

Die casting molds are essential in manufacturing. Understanding the materials used in these molds is vital for product quality. Various metals are commonly employed. Aluminum is light and resists corrosion. Zinc offers strength and ductility. Magnesium is often ignored, but it is excellent for intricate shapes. Each material serves a unique purpose.

Steel is another popular choice, known for its durability. It can withstand high pressures, making it perfect for heavy-duty applications. Yet, it may require more maintenance than other options. Bronze is less common but offers excellent wear resistance. Manufacturers sometimes overlook these materials, which can be a mistake.

The choice of material impacts production speed and costs. Different metals have varied melting points. This can affect cycle times. Careful consideration is necessary to balance efficiency and quality. If the wrong material is selected, it may lead to increased expenses. The manufacturing process is complex, and even small oversights can have significant repercussions. Understanding these nuances can help businesses make better decisions.

Comparing Die Casting to Other Manufacturing Methods

Die casting offers notable advantages compared to other manufacturing methods. It uses molten metal and pressure to produce complex shapes. The precision it achieves is remarkable. This leads to fewer defects, unlike processes like sand casting. Sand casting often requires significant finishing. This adds time and cost to production.

However, die casting has a high initial setup cost. This can deter smaller manufacturers. Yet, the long-term benefits can outweigh this. Once a mold is created, the production cost per unit lowers significantly. This makes die casting valuable for large production runs. But consider the production volume carefully before committing.

Tips: Evaluate your project's scale. If you need thousands of units, die casting might be the right choice. If only a handful is required, other methods could be more cost-effective. Always conduct a thorough cost analysis beforehand to avoid surprises later. Take your time to reflect on the specific needs of your project. This will guide you in choosing the best method for your manufacturing needs.

Comparing Die Casting to Other Manufacturing Methods

Key Factors to Consider When Choosing Die Casting Molds

When choosing die casting molds, several key factors should be considered. The material of the mold plays a crucial role. Steel molds are durable but can be expensive. Aluminum molds are lightweight and cost-effective, but may not last as long. Understanding your production volume helps to decide which material suits your needs.

Another important aspect is the design complexity. Intricate designs require precision. You may need advanced technology for such molds, which could increase costs. However, simple designs can be easier to produce, yet they might not meet market demands. Weighing these elements is essential for effective manufacturing.

Lastly, turnaround time cannot be overlooked. A quicker production lead time can boost your market competitiveness. However, rushing can lead to mistakes. Striking a balance between speed and quality is vital. Take the time to evaluate how each factor aligns with your business goals.