How to Choose the Right Ball Bearing for Your Project?

Choosing the right Ball Bearing is crucial for any engineering project. According to a report by MarketsandMarkets, the ball bearing market is expected to reach $80 billion by 2025. This growth underscores the importance of quality and precision in selecting ball bearings for various applications.

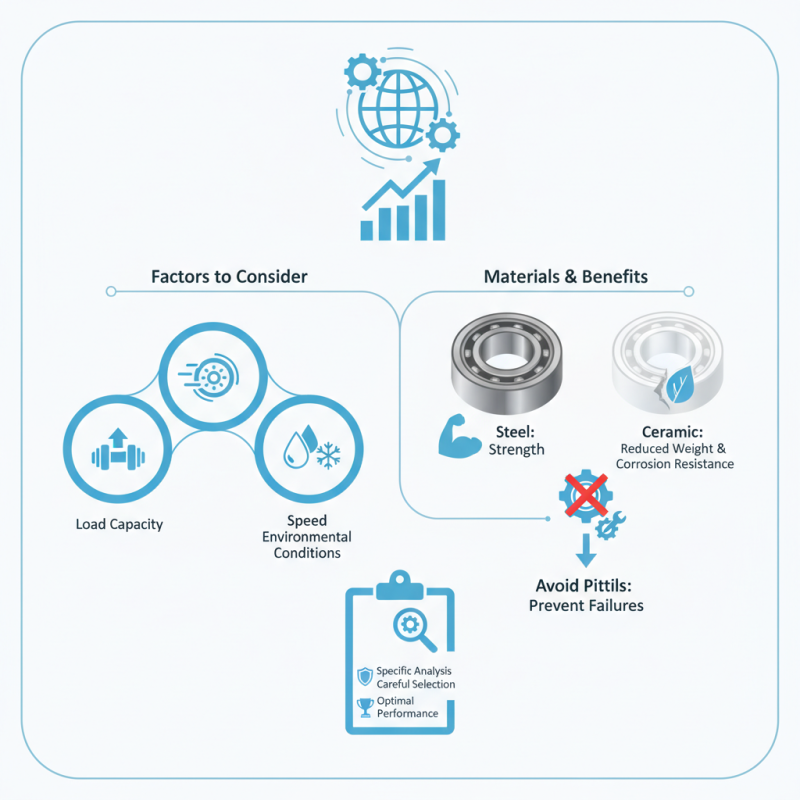

When selecting a ball bearing, consider factors such as load capacity, speed, and environmental conditions. Different materials, like steel and ceramic, also offer varying benefits and drawbacks. For instance, while steel bearings provide strength, ceramic alternatives can offer reduced weight and greater resistance to corrosion. Misjudging these elements can lead to failures or decreased efficiency in machinery.

It's essential to prioritize these details when making choices. Avoiding common pitfalls can save time and costs. Understand that not all bearings will suit every project. Each situation demands specific analysis and careful selection to ensure optimal performance.

Understanding the Basics of Ball Bearings and Their Applications

Ball bearings are essential components in machinery. They reduce friction between moving parts, allowing for smoother operation. Understanding their types and applications can help in decision-making. The right selection impacts the longevity and performance of a project.

There are several types of ball bearings, including deep groove, angular contact, and self-aligning. Each type serves different applications. For instance, deep groove ball bearings can support radial and axial loads. According to a report by the Precision Bearing Market Analysis, the global market for ball bearings is projected to reach $50 billion by 2025. This growth indicates the increasing reliance on their efficiency in various sectors, from automotive to aerospace.

Choosing the correct bearing requires knowing your project needs. Factors include load capacity, speed, and environmental conditions. Not knowing these factors can lead to failures. For example, using a bearing not rated for high speeds might result in overheating and wear. It's crucial to consult practical data and industry standards during the selection process. A thorough understanding can save time and resources in the long run.

Key Factors to Consider When Selecting Ball Bearings

When selecting ball bearings for your project, several key factors must be considered. The load capacity is crucial, as it determines the maximum load a bearing can handle. According to industry reports, ball bearings can have load ratings ranging from a few hundred pounds to several tons. It's vital to assess the weight and forces involved in your project accurately.

Another factor is the materials used in the bearings. Common materials include steel, ceramic, and plastic. Each has distinct properties. For example, steel offers high strength, while ceramic is resistant to corrosion and wear. Selecting the right material affects lifespan and performance. A study indicated that improper material choices could reduce bearing life by up to 30%.

Speed ratings also play a significant role. Bearings can operate at various speeds, but selecting one with a suitable rating is essential to avoid failure. Operating beyond the recommended speed can lead to overheating and damage. Often, users overlook this factor, resulting in costly errors. Remember, the right choice enhances efficiency and safety in your application, while a wrong choice can cause unexpected downtime.

Types of Ball Bearings and Their Specific Uses

When selecting the right ball bearing, understanding the types available is crucial. There are several common types: deep groove, angular contact, thrust, and self-aligning. Each type serves specific purposes. Deep groove ball bearings are versatile and widely used, suitable for both radial and axial loads. Angular contact bearings excel in high-speed applications, offering better performance under axial loads.

Thrust ball bearings are ideal for applications that require high axial load support. Self-aligning ball bearings can correct misalignments, making them perfect for applications with shaft deflection. According to industry reports, deep groove bearings account for over 70% of the ball bearing market due to their adaptability and effectiveness.

Tips: When selecting a ball bearing, consider load ratings. A bearing’s load rating tells you how much weight it can support. Additionally, evaluate the operating environment. Dusty or wet conditions may require sealed bearings. Always assess your project needs carefully. A wrong choice can lead to mechanical failure and increased maintenance costs.

Evaluation of Load Capacity and Performance Requirements

Choosing the right ball bearing for your project involves understanding load capacity and performance requirements. Load capacity is vital. It determines how much weight your bearing can handle without failure. If you exceed this limit, the bearing may fail. This could lead to project delays and extra costs.

Consider your application. Will it face heavy loads? Or will it operate at high speeds? Each scenario requires a different type of bearing. An insufficient load capacity can lead to premature wear. Higher performance needs may call for advanced materials.

Tip: Always factor in safety margins. It’s better to overestimate than underestimate due to unforeseen stresses.

Temperature also plays a role in performance. Extreme heat can affect the oil or grease. Check the lubrication recommendations for your selected bearing. Ignoring this can lead to reduced lifespans and failures.

Tip: Use bearings that fit your environment. A bearing’s material and design influence its performance.

Choosing the right load capacity is not always straightforward. Sometimes, the right balance is difficult to find. Rethink your choices. Assess and adjust as needed for optimal performance.

Maintenance and Lifespan Considerations for Ball Bearings

When considering ball bearings, maintenance and lifespan are crucial. Regular maintenance can extend the life of your bearings. Simple tasks, like cleaning and lubrication, can make a big difference. Dust and debris can lead to wear and tear. Regular checks can prevent costly failures.

Choosing the right lubricant is also important. Too much or too little can affect performance. Different environments require different solutions. Consider temperature, speed, and loads. And remember, bearings in harsh conditions often need more attention. Ignoring these factors may lead to premature failure, which can be frustrating.

Understanding the lifespan of a bearing is essential. Some bearings may last years, while others might fail sooner. Operating conditions greatly influence longevity. Sticking to maintenance schedules can help ensure smooth operation. However, don’t get complacent. Always be prepared for the unexpected. Keeping a close eye on performance can catch issues early.