Understanding the Essential Role of Manifolds Valves in Modern Industrial Systems

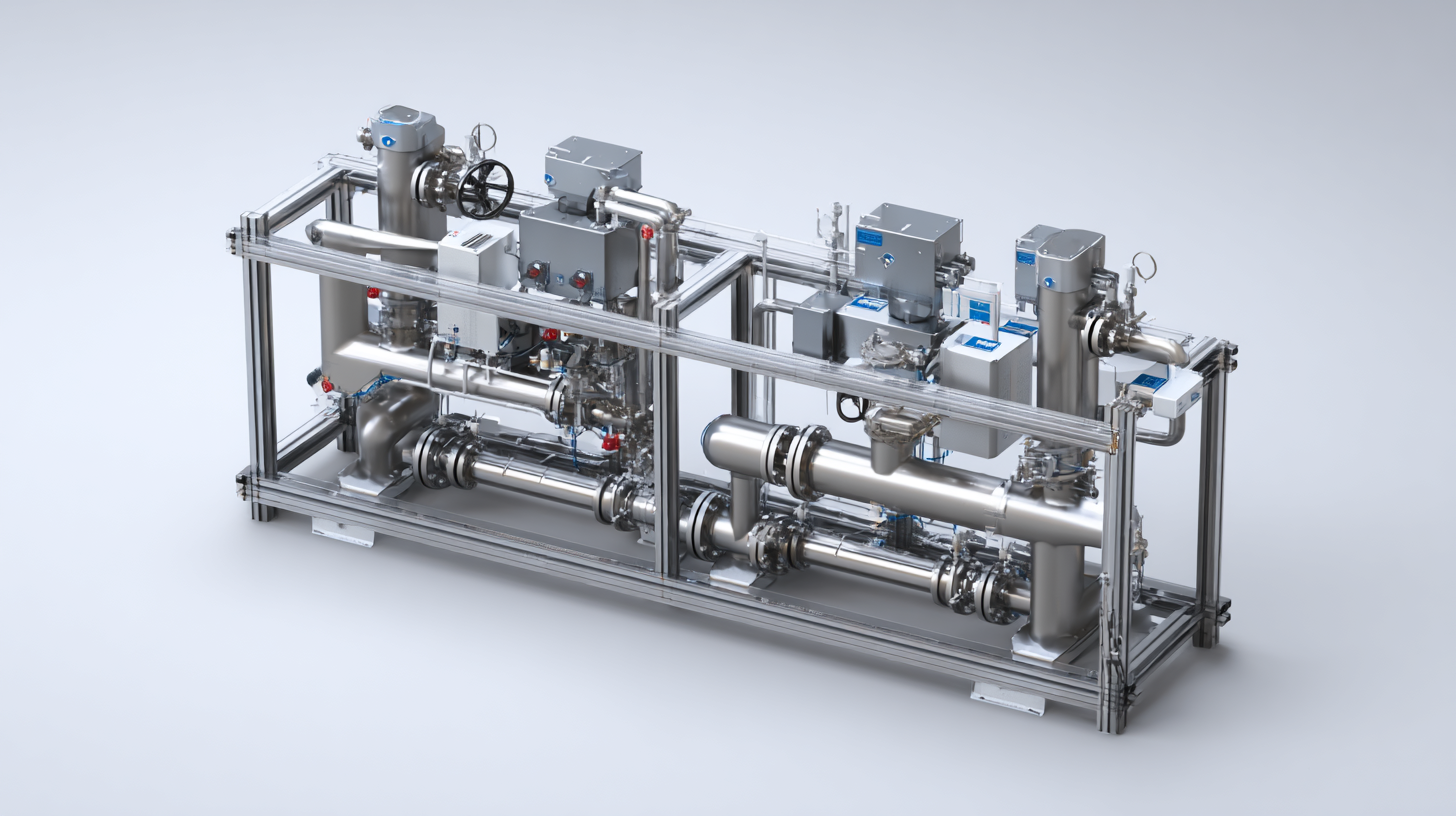

In modern industrial systems, the integration and efficiency of various components are vital for optimal performance and reliability. Among these crucial components, Manifolds Valves play a fundamental role in controlling fluid flow and ensuring seamless operation within complex systems. By consolidating multiple functions into a single unit, Manifolds Valves enhance space efficiency, reduce the potential for leaks, and simplify maintenance procedures.

This article delves into the essential roles that Manifolds Valves play in various industrial applications, providing valuable insights and tips for selecting and implementing these devices effectively. Understanding the intricacies of Manifolds Valves not only aids in improving system performance but also contributes to the overall safety and functionality of industrial processes, making them indispensable in today’s technology-driven landscape.

The Fundamental Functions of Manifolds Valves in Industrial Applications

Manifold valves play a crucial role in the efficient operation of modern industrial systems. Their primary function is to control the flow of fluids within a system, allowing for precise management of pressure and volume. According to the Flow Control & Measurement study conducted by the International Society of Automation, the use of manifold valves can lead to a reduction in energy consumption by up to 20%, highlighting their importance in optimizing operational efficiency. In industries such as oil and gas, chemical processing, and water treatment, manifold valves facilitate seamless integration and distribution of multiple fluid pathways, which increases system reliability and safety.

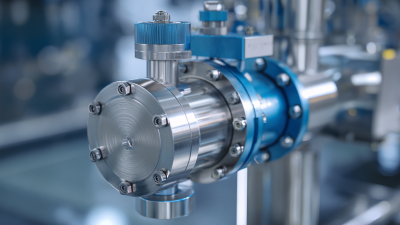

Tip: When selecting manifold valves for your application, consider options with corrosion-resistant materials and high-pressure ratings to ensure durability and longevity in harsh environments.

In addition to fluid control, manifold valves enable simplified maintenance and troubleshooting. By centralizing valve operations, technicians can efficiently isolate specific sections of a system for repairs without disrupting overall operations. A report from MarketsandMarkets indicates that the global manifold valves market is expected to grow from $4.5 billion in 2023 to $6.7 billion by 2028, driven by advancements in automation and process control. Investing in high-quality manifold valves can yield significant returns through reduced downtime and maintenance costs.

Tip: Regular inspection and testing of manifold valves can prevent unexpected failures and enhance system performance, ensuring that your operations run smoothly and efficiently.

Key Comparisons: Manifold Valves vs. Traditional Valve Systems

In the realm of industrial systems, manifold valves are revolutionizing fluid management compared to traditional valve systems. A recent report by MarketsandMarkets projects that the global manifold valve market will reach $1.2 billion by 2025, driven largely by the increased demand for efficient fluid control in diverse industries. Unlike traditional valve systems, which often consist of multiple individual valves requiring more space and complex configurations, manifold valves streamline operations by consolidating multiple functions into a single unit. This space-saving design not only enhances operational efficiency but also reduces installation and maintenance costs by 20%, according to a survey conducted by the International Society of Automation.

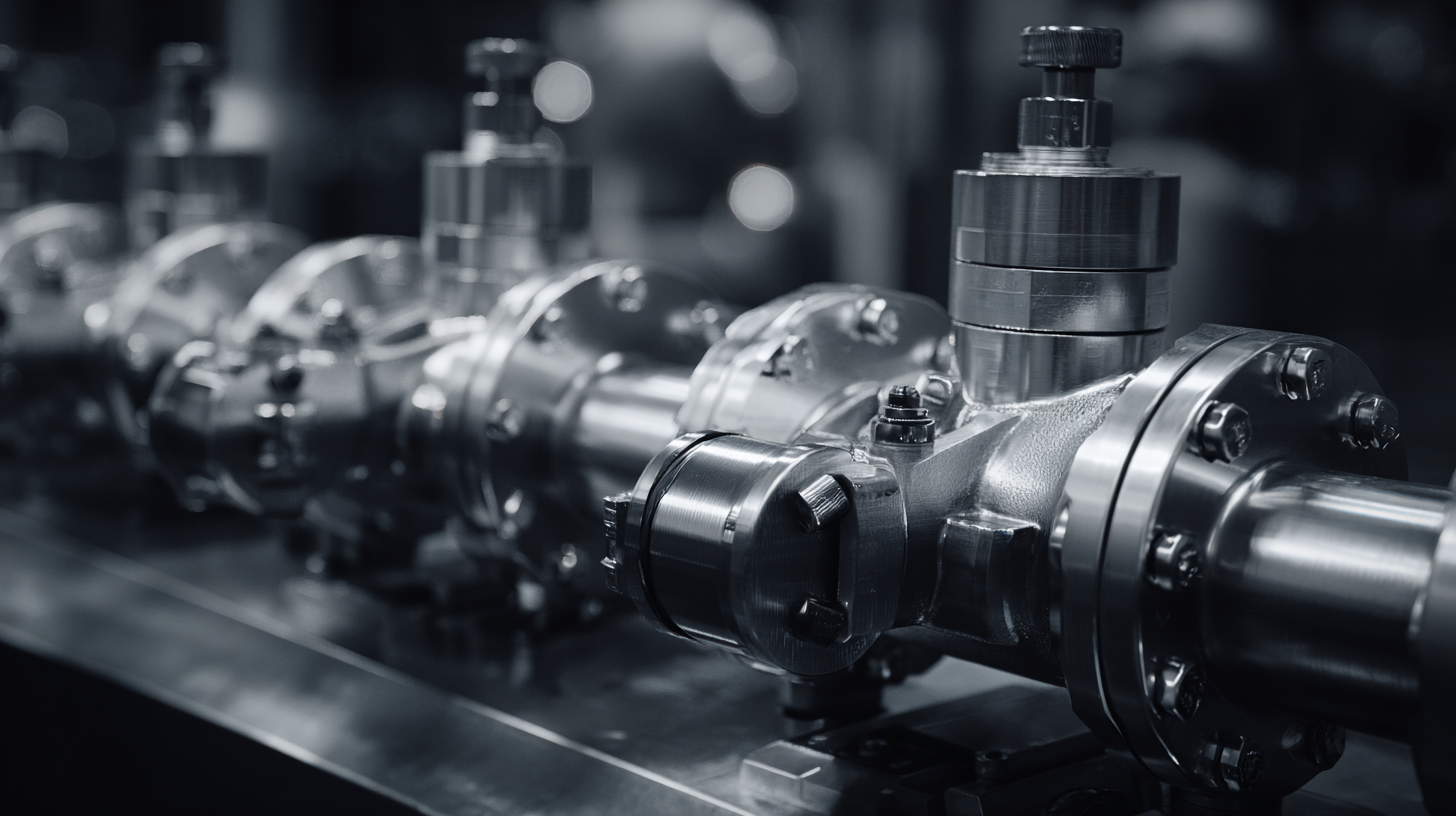

Moreover, manifold valves provide superior performance metrics, particularly in pressure control and leak prevention. Data from a study by Frost & Sullivan indicates that modern manifold valves can achieve up to 99% reliability in high-pressure applications, compared to only 85% reliability in older valve systems. This increase in reliability not only ensures safer operations but also enhances the longevity of the overall system, resulting in fewer downtimes and lower maintenance expenses. As industrial sectors continue to evolve, embracing manifold valves over traditional systems appears to be a strategic move that aligns with the goals of operational efficiency and cost-effectiveness.

Enhancing Safety and Efficiency through Manifold Valve Design

In modern industrial systems, the design and function of manifold valves are critical for enhancing operational safety and efficiency. Manifold valves serve as essential control points, allowing the precise management of fluid flow within various processes. By integrating multiple valve functions into a single assembly, these valves simplify complex piping systems, reducing potential leak points and minimizing maintenance needs. The thoughtful design of manifold valves not only streams operations but also significantly contributes to operational safety by centralizing control and providing immediate access for monitoring and adjustments.

Furthermore, the innovative engineering of manifold valves includes features that enhance both performance and reliability. By utilizing materials resistant to corrosion and wear, manufacturers can ensure that these valves maintain their integrity under high pressures and temperatures, contributing to a safer working environment. Additionally, modern manifold valve designs often incorporate automated control systems, facilitating real-time monitoring and swift response to fluctuations in system demand. This adaptability not only improves efficiency but also aids in the prevention of accidents, ensuring that industries can operate smoothly and safely in a competitive landscape.

Applications of Manifold Valves in Diverse Industrial Sectors

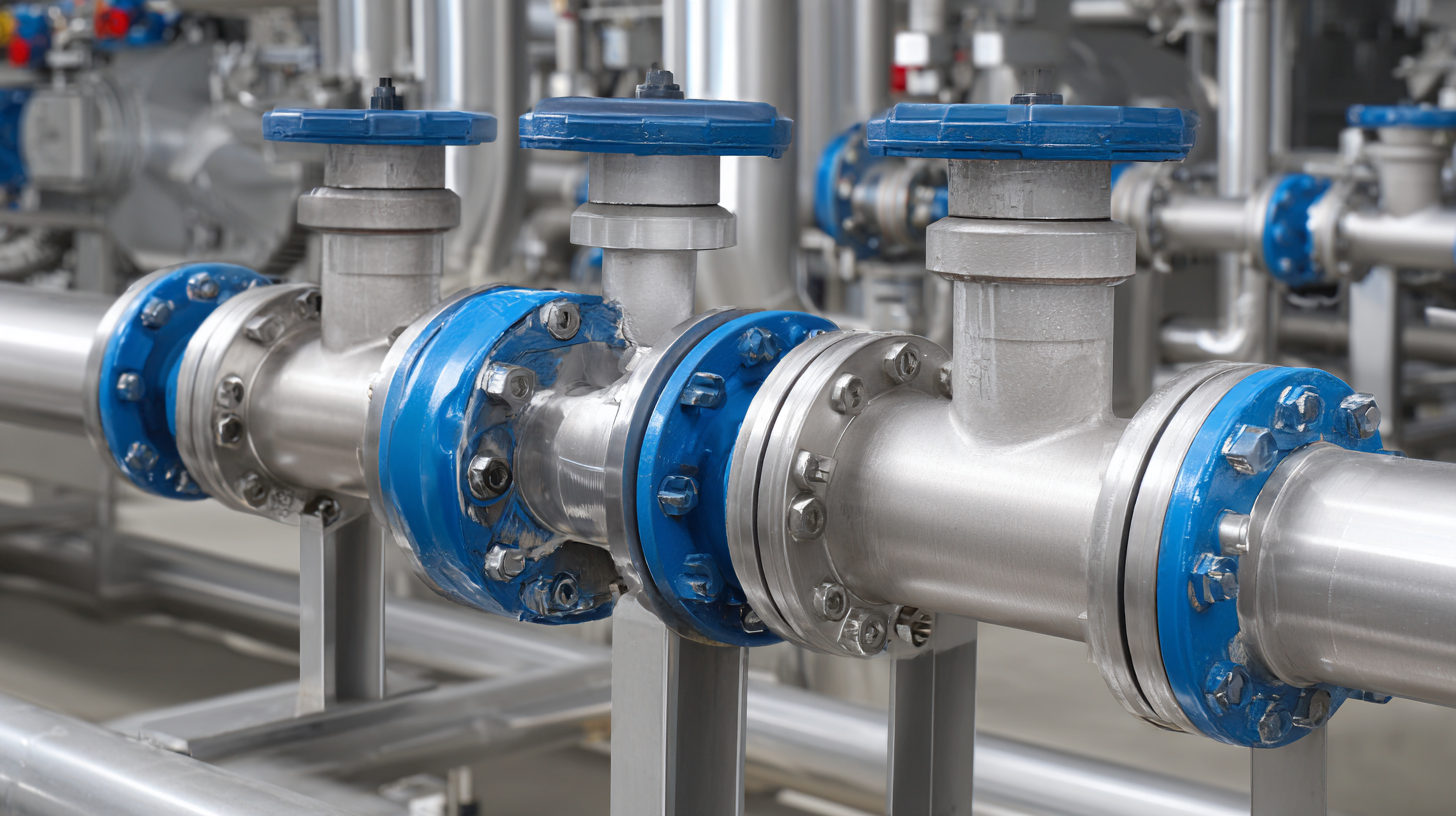

Manifold valves play a crucial role across various industrial sectors by serving as vital control points for the flow of fluids and gases. In the oil and gas industry, these valves are essential for managing pressure and ensuring safe operation. They facilitate the distribution of hydraulic fluids to different sections of pipelines, thus optimizing extraction processes and enhancing operational safety. The versatility of manifold valves ensures that complex systems can be efficiently managed, which is particularly important in environments where precision is critical.

Manifold valves play a crucial role across various industrial sectors by serving as vital control points for the flow of fluids and gases. In the oil and gas industry, these valves are essential for managing pressure and ensuring safe operation. They facilitate the distribution of hydraulic fluids to different sections of pipelines, thus optimizing extraction processes and enhancing operational safety. The versatility of manifold valves ensures that complex systems can be efficiently managed, which is particularly important in environments where precision is critical.

In the manufacturing sector, manifold valves support automation systems by controlling the flow of air or liquid in machinery. This leads to improved efficiency and reduced downtime, as they enable the quick switching between different operational states without the need for extensive manual adjustments. Additionally, in chemical processing plants, manifold valves are fundamental for maintaining precise measurements and flow rates, which are essential for product quality and consistency. Their ability to handle high pressure and temperature variations makes them indispensable across these diverse applications.

Future Innovations in Manifold Valve Technology and Their Impact

The manifold valve technology is evolving at a remarkable pace, driven by the demands for efficiency and precision in industrial applications. According to a report by MarketsandMarkets, the global manifold market is projected to reach $7.6 billion by 2025, growing at a CAGR of 5.8% from 2020. This growth can be attributed to innovations such as automation and smart technology integration, which have dramatically enhanced the performance and reliability of manifold systems.

Future innovations in manifold valves are set to incorporate advanced materials and IoT connectivity, allowing for real-time monitoring and diagnostics. Recent studies indicate that the adoption of smart manifold systems can reduce operational costs by up to 20%, as they enable predictive maintenance and minimize downtime. As industries increasingly focus on sustainability, innovative manifold designs that optimize fluid dynamics and reduce energy consumption are becoming essential. This trend not only enhances system efficiency but also aligns with global environmental goals by lowering carbon footprints in industrial operations.

Related Posts

-

How to Effectively Choose the Right Pressure Relief Valve for Your Applications

-

How to Choose the Right Swing Check Valve for Your Piping System Needs

-

Understanding the Challenges and Standards in Manufacturing the Best Backflow Preventer Valve

-

How to Choose the Right Double Check Valve for Your Application

-

Exploring Market Opportunities for Non Return Valves at the Successful 137th Canton Fair

-

Top 10 Process Valve Manufacturers from China at the 137th Canton Fair