The Future of Advanced Safety Relief Valve Technology

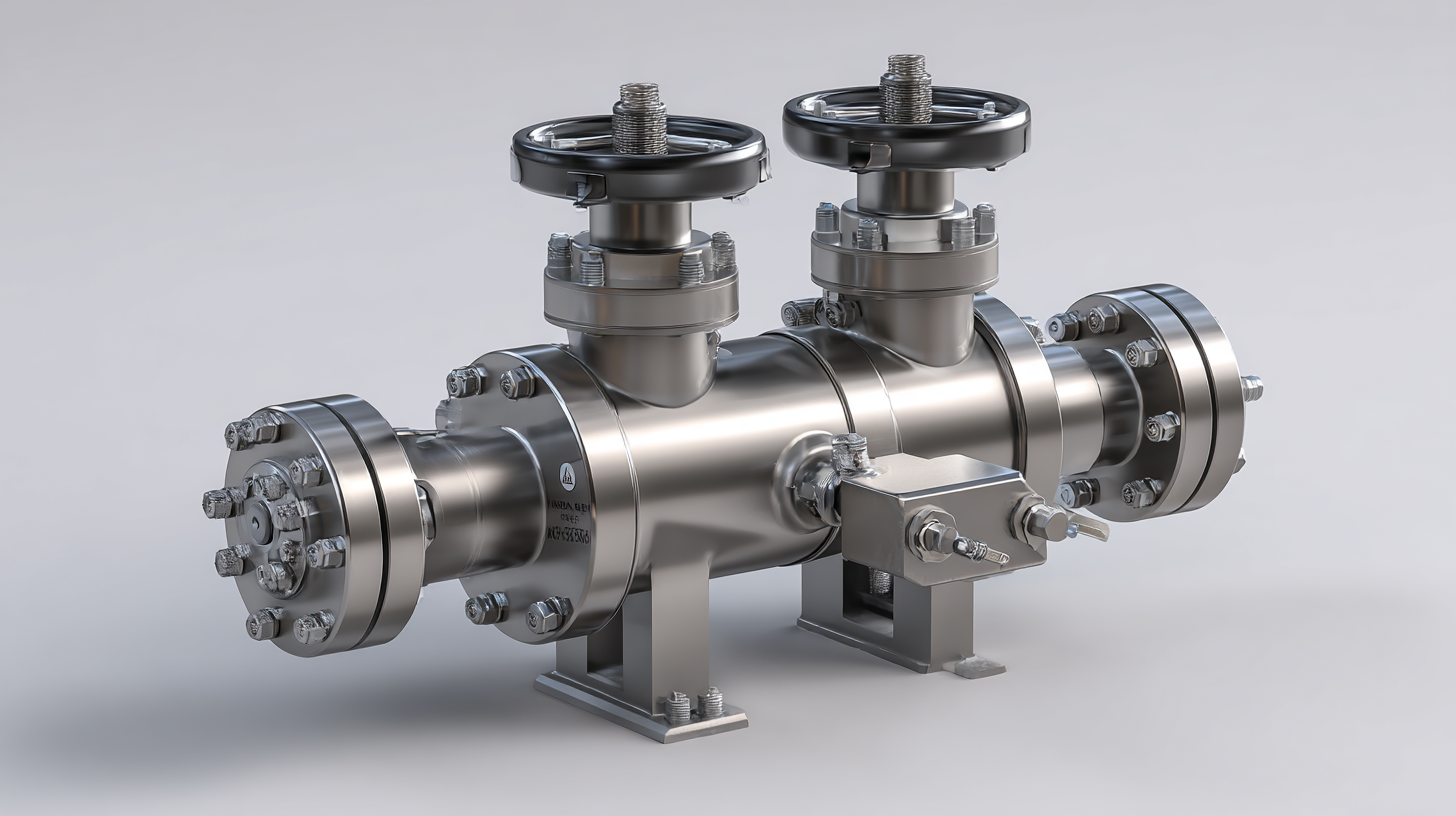

The Safety Relief Valve (SRV) is a critical component in pressure control systems across various industries, safeguarding equipment and personnel from the dangers of overpressure. According to a recent report by MarketsandMarkets, the global safety relief valve market is projected to grow from USD 2.1 billion in 2023 to USD 2.8 billion by 2028, at a CAGR of 5.8%. This growth underscores the increasing emphasis on safety regulations and the implementation of advanced technologies in valve design. However, despite innovations, problems persist, particularly with traditional SRV types, including reliability issues, wear and tear, and the inability to cope with fluctuating process conditions. As industries strive for improved operational efficiency and enhanced safety, understanding these issues is paramount for future advancements in safety relief valve technology.

Benefits of Advanced Safety Relief Valve Technology in Industrial Applications

The integration of advanced safety relief valve technology into industrial applications marks a significant advancement in process safety management. These modern valves not only provide reliable pressure relief but also come equipped with enhanced features like remote monitoring and smart diagnostics. By utilizing these capabilities, industries can achieve a higher level of operational efficiency while minimizing risks associated with pressure fluctuations. This proactive approach to safety can lead to a reduction in maintenance costs and downtime, ultimately benefiting the bottom line.

In addition to operational efficiencies, advanced safety relief valves contribute to environmental sustainability. By preventing leaks and ensuring that processes operate within safe parameters, these technologies help companies adhere to stringent regulatory requirements. Emphasizing reliability and responsiveness, they mitigate the potential for hazardous situations, allowing for a smoother workflow. Moreover, the data analytics provided by smart valves empower engineers to make informed decisions, facilitating continuous improvement in safety protocols within the industrial sector. The future of industrial applications is undoubtedly brighter with the implementation of these cutting-edge solutions.

The Future of Advanced Safety Relief Valve Technology

This chart illustrates the benefits of advanced safety relief valve technology in various industrial applications, focusing on efficiency, safety, and cost-effectiveness.

How Enhanced Design Improves Reliability and Safety Standards

The advancement in safety relief valve technology is revolutionizing industries by significantly improving reliability and safety standards. Enhanced designs now incorporate sophisticated materials and engineering techniques that not only withstand extreme conditions but also offer greater precision in operation. The development of smart sensors and digital monitoring systems allows for real-time data tracking, enabling immediate response to potential failures and ensuring that safety measures are always in place.

Furthermore, the integration of advanced testing protocols during the manufacturing process guarantees that each valve meets stringent safety regulations. Innovative design features, such as modular components and ease of maintenance, also contribute to reducing downtime, thereby enhancing operational efficiency. By focusing on these enhancements, manufacturers can ensure that safety relief valves not only perform optimally under pressure but also contribute to a culture of safety within organizations. As these technologies evolve, industries can anticipate a future where safety standards are consistently met or exceeded, safeguarding equipment and personnel alike.

The Future of Advanced Safety Relief Valve Technology - How Enhanced Design Improves Reliability and Safety Standards

| Aspect | Description | Benefit | Impact on Safety Standards |

|---|---|---|---|

| Material Advancements | Use of advanced alloys and corrosion-resistant materials. | Increased durability and longevity. | Meets higher industry standards for reliability. |

| Smart Technology | Integration of IoT for real-time monitoring. | Improved predictive maintenance capabilities. | Enhances risk management and operational safety. |

| Design Innovations | Use of simulation and modeling in design process. | Reduces failure rates during operation. | Supports compliance with stricter safety regulations. |

| Testing Protocols | Enhanced protocols for testing under extreme conditions. | Higher confidence in performance data. | Establishes new benchmarks for safety testing. |

| Regulatory Compliance | Alignment with international safety and environmental standards. | Facilitates global market access. | Reduces liability and enhances brand reputation. |

Cost Efficiency Through Innovative Materials and Manufacturing Processes

As the industry evolves, the demand for advanced safety relief valves becomes increasingly significant, particularly in the context of cost efficiency. Innovative materials and manufacturing processes play a pivotal role in meeting these demands. Recent reports indicate that the implementation of lightweight composite materials can reduce manufacturing costs by up to 30% while enhancing the overall performance of safety relief valves. For instance, the use of high-strength polymers not only lowers weight but also increases resistance to corrosion, thereby extending the lifespan of the valves.

Tip 1: When selecting materials for safety relief valves, consider both the long-term performance and the initial cost. Investing in high-quality materials may offer better value over time due to reduced maintenance and replacement needs.

Additionally, advancements in additive manufacturing techniques, such as 3D printing, are revolutionizing the production of safety relief valves. A study by the American Society of Mechanical Engineers (ASME) suggests that utilizing 3D printing can decrease lead times by 50% and allow for complex geometries that optimize flow dynamics, thus improving safety performance without significantly raising costs.

Tip 2: Collaborate with manufacturers who prioritize innovative production methods. This can lead to customized solutions tailored to specific operational environments, ultimately driving efficiency and enhancing safety measures.

Integration of Smart Technology in Safety Relief Valves

The integration of smart technology into safety relief valves represents a significant leap forward in the field of pressure management. Traditional safety relief valves have been designed primarily to operate reliably under pressure, but with the advent of smart technology, these valves can now offer enhanced monitoring and control capabilities. By incorporating sensors and IoT connectivity, these advanced valves provide real-time data on their operational status, allowing for proactive maintenance and improved reliability. This shift not only enhances safety standards but also reduces downtime, which can be costly in industrial settings.

Furthermore, the application of predictive analytics in safety relief valves enables enhanced decision-making processes. By analyzing data collected from these smart devices, engineers can anticipate potential failures and identify trends that may pose risks. This level of insight allows for timely interventions and adjustments, minimizing the risk of hazardous situations. As industries increasingly adopt smart technology, the future of safety relief valves is not just about compliance with safety regulations, but also about harnessing data to create more resilient and efficient operational environments. Innovations in this area will undoubtedly shape the future landscape of industrial safety.

Future Trends: Automation and IIoT in Safety Relief Systems

Advanced safety relief valve technology is poised to undergo transformative changes with the integration of automation and the Industrial Internet of Things (IIoT). As we transition into Industry 4.0, safety relief systems will leverage enhanced connectivity and real-time data analytics to improve performance and reliability. These advancements will not only streamline operations but also support predictive maintenance, reducing the likelihood of unexpected failures.

Tips for leveraging automation and IIoT in safety relief systems include:

- Invest in Smart Sensors: Incorporating smart sensors can provide real-time monitoring and diagnostics of relief valves. This technology can alert operators about potential issues before they escalate, enhancing safety and operational efficiency.

- Utilize Data Analytics: Implement data analytics tools to interpret the vast amounts of data generated by IIoT devices. Analyzing this data can offer insights into valve performance trends and help identify areas for improvement.

- Embrace Cloud Solutions: Cloud-based platforms enable centralized data management, facilitating easier integration of safety relief systems with other industrial processes. This approach supports collaboration and enhances decision-making efficiency across the organization.

With these strategies, industries can harness the full potential of advanced safety relief valve technology, leading to safer and more efficient operations.