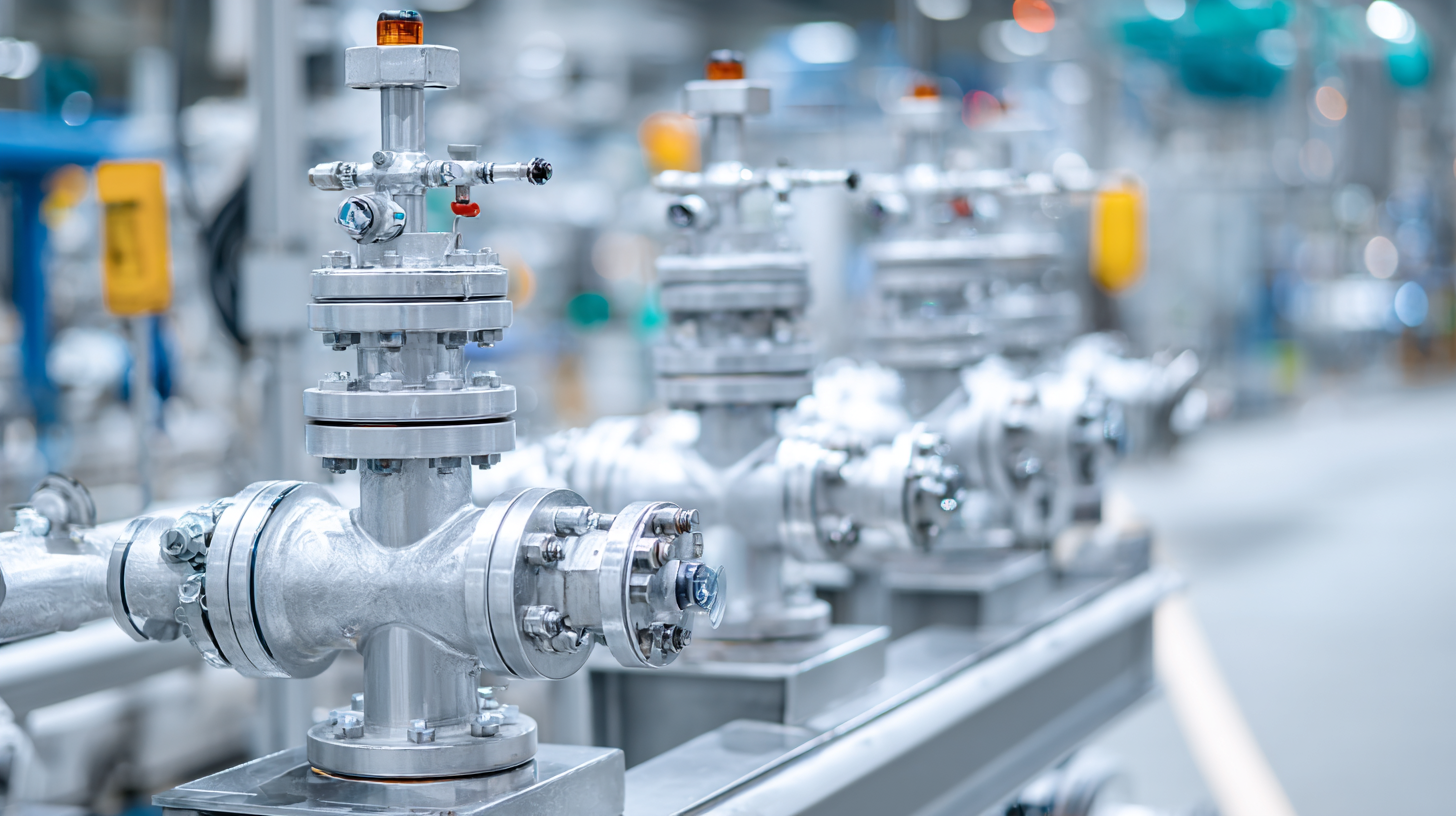

Understanding Global Industry Standards for Best Cryogenic Valves in Modern Applications

In the rapidly evolving realm of modern industrial applications, the significance of high-quality Cryogenic Valves cannot be overstated. As industries such as liquefied natural gas (LNG) and cryogenic transportation continue to expand, the demand for reliable cryogenic valves is projected to surge, with the global cryogenic valve market expected to reach a valuation of over $3.5 billion by 2026, according to recent industry analyses by Mordor Intelligence.

These valves play a crucial role in maintaining the integrity and efficiency of systems operating at extremely low temperatures, making the selection of a reputable supplier paramount. Companies must navigate a complex landscape of standards and certifications to ensure that they procure valves that not only meet stringent safety requirements but also optimize performance in their specific applications.

Understanding the nuances of these global industry standards is vital for organizations aiming to enhance operational reliability and competitiveness in their markets.

The Growing Importance of Cryogenic Valves in Diverse Industries by 2025

As industries increasingly adopt advanced technologies and strive for efficiency, the significance of cryogenic valves is poised to grow substantially by 2025. These specialized valves, designed to operate at extremely low temperatures, play a crucial role in applications ranging from liquefied natural gas (LNG) transportation to medical and aerospace fields. Their ability to maintain integrity and performance under severe conditions makes them indispensable in ensuring safety and reliability in operations.

When selecting cryogenic valves for modern applications, consider focusing on quality and compliance with global industry standards. For example, always opt for valves made from materials specifically designed for cryogenic use to prevent failures caused by extreme cold. Regular maintenance is also essential; implement a schedule for inspections to identify wear and tear before they lead to larger issues.

Additionally, staying informed about industry trends and evolving technologies can provide a competitive edge. Engage with manufacturers and participate in forums to gain insights into best practices and innovations in cryogenic valve design. This proactive approach will not only enhance operational efficiency but also ensure that businesses remain compliant with increasing regulatory demands.

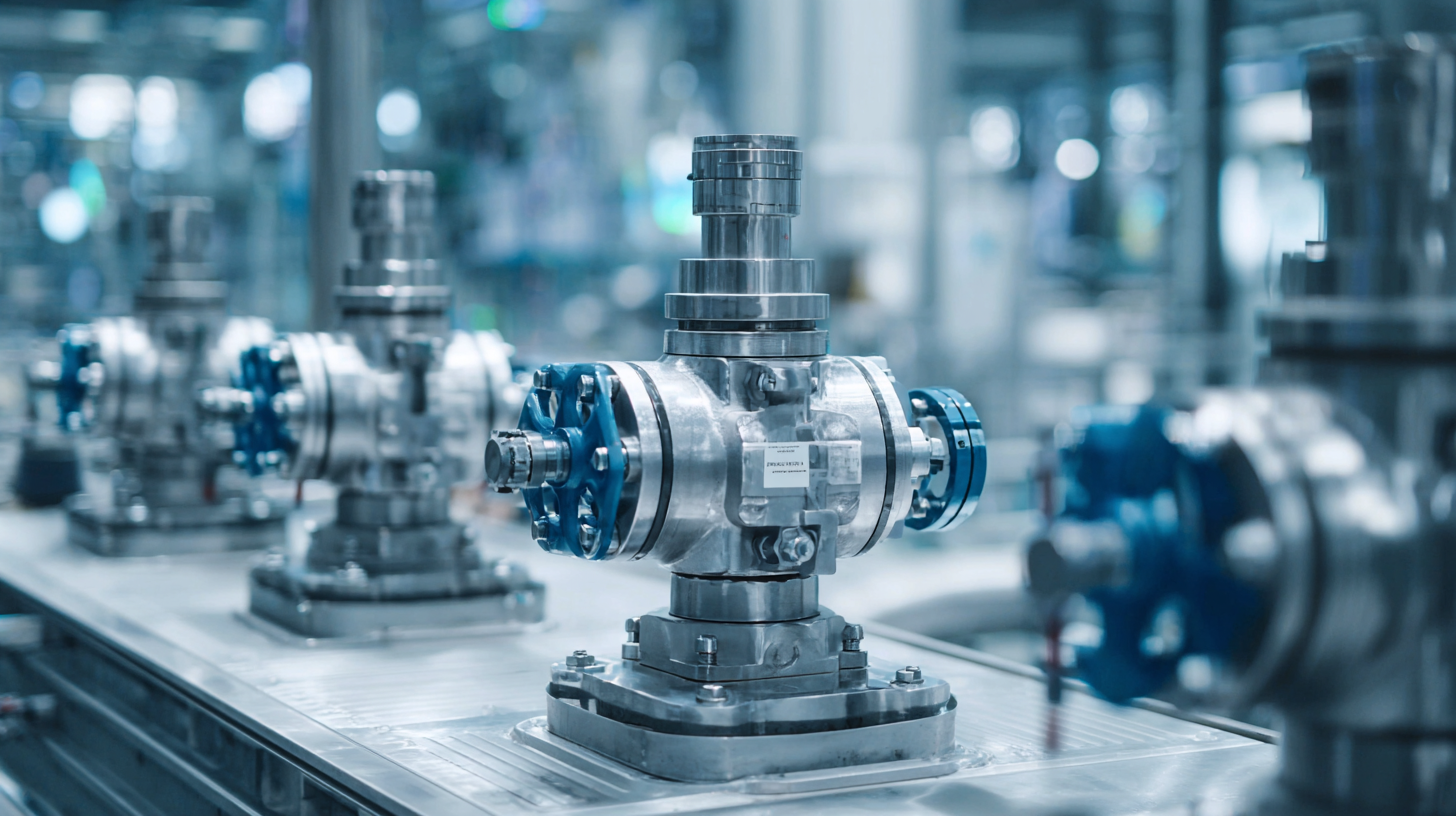

Key Industry Standards Influencing Cryogenic Valve Quality and Performance

When it comes to cryogenic valves, understanding the key industry standards is essential for ensuring quality and performance in modern applications. The American Society of Mechanical Engineers (ASME) provides vital guidelines that govern the design and manufacturing processes of these critical components.

The ASME B31.3 standard, which relates to process piping, outlines the requirements for the safe and efficient operation of cryogenic systems, emphasizing material selection and fabrication techniques that can withstand extreme temperatures.

In addition to ASME standards, the International Organization for Standardization (ISO) plays a pivotal role in shaping the cryogenic valve industry. ISO 28921, for example, addresses the testing of cryogenic valves, ensuring their reliability under severe conditions. These standards not only promote safety and interoperability but also enhance the longevity and efficiency of cryogenic systems used in various industries, including aerospace, healthcare, and energy.

By adhering to these benchmarks, manufacturers can create valves that not only meet user expectations but also comply with regulatory requirements, ultimately leading to improved performance in modern cryogenic applications.

Market Drivers: The Role of Technological Advancements in Cryogenic Valve Development

In the rapidly evolving landscape of cryogenic valve technology, market drivers play a pivotal role in shaping development. One of the leading catalysts for innovation is the relentless progression of technological advancements. As industries increasingly demand higher reliability and efficiency, manufacturers are compelled to integrate cutting-edge technologies into their cryogenic valves. This includes automation features that enhance operational performance and reduce the risk of human error. Technologies such as advanced materials and improved manufacturing processes also contribute significantly, allowing for valves that can withstand extreme temperatures and corrosive environments.

Moreover, the rise of industries that utilize cryogenic processes, including aerospace, liquefied natural gas, and medical applications, further drives the need for sophisticated valve solutions. The integration of digital monitoring systems allows for real-time data collection and predictive maintenance, enabling companies to optimize their operations and extend the lifespan of their equipment. As these technological trends continue to unfold, stakeholders in the cryogenic valve market must stay attuned to advancements that offer enhanced safety, efficiency, and sustainability. This proactive approach not only ensures compliance with global industry standards but also solidifies a competitive edge in the market.

Understanding Global Industry Standards for Best Cryogenic Valves in Modern Applications

| Application Area | Material | Temperature Range (°C) | Pressure Rating (bar) | Key Features |

|---|---|---|---|---|

| Cryogenic Storage | Stainless Steel | -196 to 50 | 10-40 | Low Leakage, Lightweight |

| LNG Transportation | Carbon Steel | -162 to 70 | 10-100 | Corrosion Resistant, High Reliability |

| Biomedical Applications | Bronze | -196 to 150 | 1-20 | Sterilizable, Biocompatible |

| Aerospace | Aluminum Alloy | -250 to 80 | 5-50 | Lightweight, High Strength |

| Energy Production | Nickel Alloys | -196 to 400 | 20-300 | High Temperature Resistance, Durability |

Emerging Applications: Where Best Cryogenic Valves Are Making an Impact

In recent years, cryogenic valves have gained significant traction across various emerging applications, particularly in the aerospace, energy, and medical sectors. For instance, a report by MarketsandMarkets estimates that the global cryogenic valve market is projected to reach $3.5 billion by 2025, driven largely by the increasing demand for liquefied natural gas (LNG) infrastructure. These valves play a critical role in managing the safe and efficient flow of cryogenic liquids, making them essential components in the burgeoning LNG market.

In the aerospace industry, the increasing reliance on cryogenic fuels for propulsion systems underscores the pivotal role of cryogenic valves. According to a study by the National Aeronautics and Space Administration (NASA), the use of cryogenic fluids like liquid oxygen and liquid hydrogen can boost the performance of rocket engines by up to 30%. This increasing adoption in spacecraft design necessitates the development of valves that can handle extreme temperatures and pressures, thereby emphasizing the importance of advanced materials and manufacturing techniques in their production. The impact of best cryogenic valves extends to medical applications as well, where they support technologies like MRI machines and oxygen delivery systems, enhancing patient care while ensuring safety and reliability.

Future Trends: Predicting the Next Innovations in Cryogenic Valve Technology

As the cryogenic industry evolves, we are witnessing significant innovations in valve technology that enhance efficiency and safety. One trend is the integration of smart technologies, allowing valves to be monitored remotely for performance metrics and maintenance alerts. This real-time data not only prevents unexpected failures but also optimizes the overall system's reliability. Expect to see more valves equipped with IoT capabilities, a move that will transform how facilities manage their cryogenic systems.

**Tip:** When selecting cryogenic valves, ensure they are compatible with existing systems and equipped with the latest technology for enhanced performance and ease of monitoring.

Another promising trend is the development of advanced materials designed to withstand extreme temperatures and pressures. Research into lightweight yet durable composites may lead to valves that are not only more efficient but also easier to install and maintain. Manufacturers are also focusing on minimizing leakage through innovative designs, which is crucial for maintaining the integrity of cryogenic environments.

**Tip:** Always inquire about the material specifications and design features of cryogenic valves to ensure they meet the stringent safety and efficiency standards required in your applications.

Understanding Global Industry Standards for Best Cryogenic Valves

This chart depicts the projected global market growth for cryogenic valves in various industries over the next five years. The data highlights the increasing demand driven by advancements in technology and applications in sectors like LNG, aerospace, and medical.