What is a Lamination Machine and How Does It Work?

In the world of printing and document finishing, the Lamination Machine plays a critical role. It enhances durability by applying a protective layer to various materials. According to industry expert John Smith, “A Lamination Machine is essential for preserving vital documents.” This statement reflects the ongoing demand for effective document protection in offices and schools.

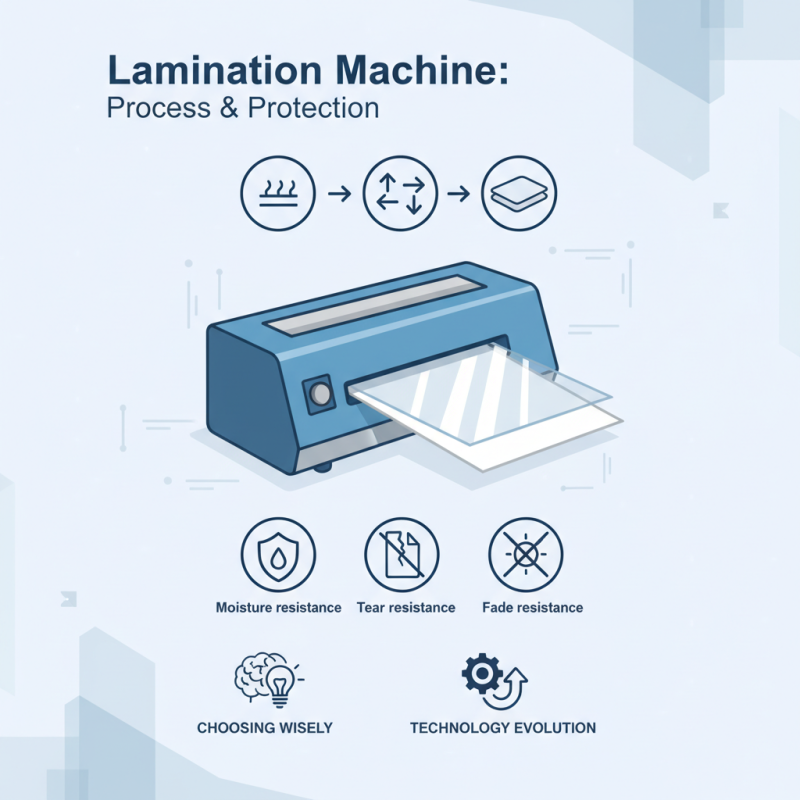

The Lamination Machine operates through a straightforward process. It uses heat and pressure to bond a plastic film to the surface of paper, photographs, or cardstock. A well-laminated document resists tears, moisture, and fading. Yet, not all machines are created equal. Some models struggle with uneven surfaces, producing less-than-perfect results.

Consideration of these factors can help users choose wisely. Choosing the right Lamination Machine is crucial for achieving desired outcomes. It’s not just about functionality; it's about making a sound investment for quality preservation. The industry continues to evolve, and with it, improvements in lamination technology. However, challenges remain, pushing users to find machines that truly meet their needs.

What is a Lamination Machine?

A lamination machine is a device used to protect and enhance documents, photos, and other materials. It uses heat and pressure to bond a thin layer of plastic film to the surface of the item. This process significantly increases durability and improves resistance to wear, moisture, and UV light. According to industry reports, the global lamination machine market is expected to grow at a CAGR of 4.5% by 2027, demonstrating the increasing demand for laminated products.

These machines come in various types, including pouch laminators and roll laminators. Pouch laminators are widely used in offices and homes for simple document protection. Roll laminators are more suitable for large-scale operations. The choice of machine often depends on the desired output. However, users sometimes face challenges, such as uneven heat distribution or film jams. These issues can cause frustration and may lead to wasted materials.

While lamination adds a professional touch, it’s important to consider the environmental impact. The plastic film used is not biodegradable. Many users fail to reflect on waste generation associated with laminating. As the eco-conscious movement gains momentum, companies are exploring biodegradable alternatives. Balancing protection and sustainability is a growing challenge in the industry.

| Feature | Description |

|---|---|

| Purpose | To protect papers or other materials by encasing them in a thin layer of plastic. |

| Types | Cold lamination, thermal lamination, and pouch lamination. |

| Common Uses | ID cards, certificates, business cards, and photos. |

| How It Works | A lamination machine uses heat or pressure to bond a layer of plastic over a sheet of paper. |

| Benefits | Increases durability, enhances appearance, and provides protection against moisture. |

| Maintenance | Regular cleaning of rollers and ensuring proper heating elements to prevent malfunctions. |

History and Evolution of Lamination Technology

Lamination technology has a fascinating history. It dates back to the early 20th century. Initially used in printing, lamination has expanded greatly since then. Early machines were large and cumbersome. They often required manual operation. The evolution of materials and processes has significantly altered this landscape.

By the 1950s, the lamination process became more automated. Advances in adhesive technologies improved durability. According to a report from the Laminating Industry Association, the market for laminating machines grew by 8% annually during this time. This growth has led to innovations aimed at efficiency and speed. Today’s machines have multiple functions, including cold and hot lamination.

Despite progress, challenges remain. Some lamination processes still create waste. Certain materials are difficult to recycle. The industry must find solutions for these issues. Modern research suggests that almost 30% of laminated products end up in landfills. This highlights the need to improve sustainability. Balancing quality, efficiency, and environmental responsibility continues to be a complex task.

Key Components of a Lamination Machine

A lamination machine is essential for protecting and enhancing documents. Understanding its key components reveals how it operates. The main parts include the rollers, heating elements, and control panel.

The rollers press the film onto the document. They create a strong bond through heat and pressure. This process ensures that the laminate is secure and durable. The heating elements play a critical role. They melt adhesive within the laminating film. Without adequate heat, lamination might fail, leading to bubbles or uneven surfaces.

The control panel is another vital component. It allows users to adjust temperature and speed. If settings are incorrect, results can be disappointing. An inexperienced operator may overlook simple adjustments. This can lead to wasted materials and time. Proper understanding of each part enhances the efficiency and quality of lamination.

Operating Principles: How Lamination Machines Function

Lamination machines are essential tools in various industries. They serve to protect and enhance documents by covering them in a thin layer of plastic. The process involves heat, pressure, and adhesive properties to bond the plastic to the paper. These machines can be found in offices, schools, and print shops.

Operating principles of lamination machines rely on their components. A heated roller system helps melt the adhesive. Papers are fed through the machine, sandwiching them between two layers of plastic film. As the papers pass through, heat activates the adhesive, creating a firm bond. It’s interesting how temperature control is crucial. Too hot, and the paper can warp; too cool, and the adhesive won’t attach properly.

Maintaining lamination machines is often overlooked. Dust or adhesive residue can lead to uneven lamination. Operators should regularly check for these issues. Proper maintenance does improve output quality. It is sometimes frustrating, but attention to minor details pays off in the end. A well-functioning machine not only saves time but also produces better outcomes.

Lamination Machine Production Rate by Type

This chart shows the production rates of different types of lamination machines measured in units per hour. Each type of laminator has its unique operational efficiency, influencing the choice of lamination machine based on production needs.

Applications and Benefits of Using Lamination Machines

Lamination machines offer a variety of applications in different industries. They are commonly used to protect documents. Think of menus, ID cards, and important certificates. The lamination process adds a layer of plastic. This helps resist water, dirt, and wear over time. Small businesses often benefit from these machines. A laminated poster can attract customers more effectively than a non-laminated one.

In educational settings, lamination machines help preserve materials. Teachers can laminate worksheets for reuse. This not only saves paper but also enhances durability. A well-laminated map or chart can last for years. It’s interesting, however, that sometimes laminated items can reflect too much light. This can make them hard to read in bright conditions. Finding the right balance in lamination thickness is crucial.

Environmental concerns also arise with lamination. The plastic used can harm ecosystems if not disposed of properly. Some companies are exploring biodegradable options. Yet, these innovations are still in their infancy. Users should consider both benefits and drawbacks. The efficiency of a lamination machine might come with hidden costs. Awareness is essential for making informed decisions.