What is a Motorized Valve and How Does It Work?

Motorized Valves play a crucial role in modern automation and control systems. According to a report by MarketsandMarkets, the global market for motorized valves is projected to reach $6.7 billion by 2026, growing at a CAGR of 6.9%. This growth reflects the increasing demand for efficient fluid control in various industries, including oil and gas, water treatment, and HVAC systems.

These valves work by using electric motors to control the flow of liquids and gases, providing precise regulation. They can respond to control signals in real-time, enhancing system efficiency. However, challenges remain. Maintenance issues can arise, and users often face difficulties with calibration. Moreover, the understanding of motorized valve technology is not widespread, which leads to misuse and inefficiency in operations.

Proper installation and regular checks are essential for maximizing performance. As industries evolve, so does the technology. Adapting to these advancements is necessary for optimization. This highlights the need for targeted training and education on motorized valves. Failure to address these gaps could hinder productivity and waste resources.

What is a Motorized Valve?

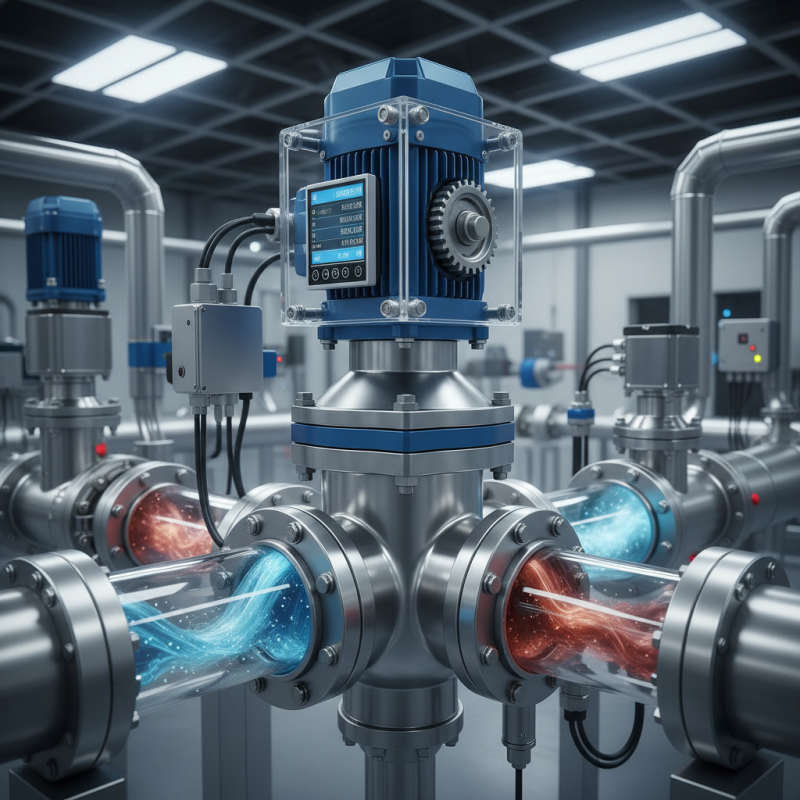

A motorized valve is an essential component in many mechanical systems. It is designed to control the flow of liquids or gases through pipes. This valve operates using an electric actuator, which moves the valve to open or close it. This action allows for precise flow regulation, making it vital in industrial applications.

Understanding how a motorized valve works can improve efficiency. The design typically includes a valve body, an electric motor, and a control system. When the control system sends a signal, the motor adjusts the valve position. This ensures that flow is managed according to specific needs. Operators can monitor the valve's status remotely, enhancing convenience.

Tips: Regular maintenance is crucial. Check for leaks and valve responsiveness frequently. A malfunctioning valve can disrupt system operations, leading to costly downtime. It's also important to calibrate the control system. This helps maintain accurate flow rates. Sometimes, users overlook these checks, assuming everything is fine.

In summary, knowing the basics of motorized valves is beneficial. Familiarize yourself with their components and operations. Seek professional advice if you're uncertain about maintenance tasks. Remember, minor adjustments can lead to significant improvements in performance over time.

Components of a Motorized Valve

Motorized valves are essential components in various systems. They automate the flow of fluids, enhancing efficiency. Understanding their components helps us appreciate their function.

The actuator is a key part, driving the valve mechanism. It can be electric, pneumatic, or hydraulic. The actuator controls the valve position based on signals. This control allows for precise flow regulation. The valve body is another crucial component. It houses the internal mechanism. The internal parts, like the disc or ball, determine flow direction. They interact directly with the fluid.

Seals and packing materials also play a role. They prevent leaks, ensuring safe operation. Sometimes, these components wear out, leading to issues. Regular maintenance is crucial. Connections and fittings are often overlooked. However, they are vital for system integrity. Each component works together, forming a cohesive unit. We must reflect on the importance of each part for optimal performance.

Motorized Valve Efficiency Comparison

This chart illustrates the efficiency parameters of a motorized valve, including flow rate, power consumption, response time, and durability. Each metric is critical in evaluating the overall performance and suitability of motorized valves in various applications.

How Motorized Valves Function Mechanically

Motorized valves are essential in controlling fluid flow in various systems. They operate using electrical signals to adjust valve position. These valves can open or close fully or partially, depending on the application. Understanding their mechanical function is key to utilizing them effectively.

The mechanism of a motorized valve typically involves an actuator. This device is powered by either electricity or pneumatic pressure. When activated, it turns a stem that adjusts the valve's position. It’s fascinating how small movements can control large amounts of fluid. Remember that improper installation can lead to failures or inefficiencies.

Tips: Always check the compatibility of the actuator with the valve type. Regular maintenance is crucial for optimal performance. Look for signs of wear or corrosion that might indicate a need for replacement.

Additionally, observe the response time of the valve during operation. Slow response can hinder system performance. Reflecting on your setup might reveal areas for improvement. Regularly testing the actuators can help catch potential issues early.

Applications of Motorized Valves in Various Industries

Motorized valves play a vital role in many industries. They are used to control the flow of liquids and gases automatically. In manufacturing plants, these valves help manage processes efficiently. For example, they regulate water flow in cooling systems. This ensures that machinery operates within safe temperature ranges.

In the oil and gas industry, motorized valves control fluid transfer. They can shut off flow to prevent spills. These valves are crucial for safety in high-pressure environments. In HVAC systems, motorized valves ensure proper air circulation. This improves energy efficiency and comfort in buildings.

However, choosing the right valve can be challenging. Factors like pressure, temperature, and compatibility matter. Different industrial applications require specific designs. Sometimes, improper valve selection can lead to failures. Regular maintenance is essential to avoid leaks and ensure durability. Understanding the needs of each application helps in making better choices.

Benefits of Using Motorized Valves Over Manual Valves

Motorized valves are increasingly popular in various industrial applications. They offer considerable advantages over manual valves. One major benefit is automation. Automated systems can adjust flow rates rapidly and accurately. This eliminates the need for human intervention. As a result, you can reduce labor costs and minimize human error.

Efficiency is another advantage. Motorized valves operate quickly, allowing for precise control over processes. This is critical in industries where timing is essential. For instance, in chemical processing, even a small delay can lead to significant issues. Utilizing motorized valves enhances responsiveness and ensures processes run smoothly.

**Tip:** Regular maintenance is important. Check for wear and tear on motors and seals. Keeping them in good condition prevents unexpected breakdowns.

Consider energy savings as well. Motorized valves can be integrated with sensors to optimize system performance. This helps to conserve energy, which is important for environmental sustainability. They can adjust automatically based on real-time data. However, be mindful that installation costs may be higher upfront.

**Tip:** Analyze the total cost of ownership. This includes installation, maintenance, and operational expenses over time. Investing wisely can lead to substantial savings.

What is a Motorized Valve and How Does It Work? - Benefits of Using Motorized Valves Over Manual Valves

| Feature | Motorized Valves | Manual Valves |

|---|---|---|

| Operation | Automated, remote-controlled | Manual actuation by hand |

| Response Time | Fast, can be controlled instantly | Slower, dependent on human reaction |

| Installation Complexity | Requires electrical connections | Simple, no electrical work needed |

| Control Methods | Programmable, can integrate with sensors | Mechanical lever operation only |

| Maintenance | Requires regular checks on electrical components | Generally lower maintenance needs |

| Applications | Used in automated systems, HVAC, and industrial applications | Suitable for simple systems, residential use |