The Essential Role of Non Return Valves in Preventing Backflow in Industrial Systems

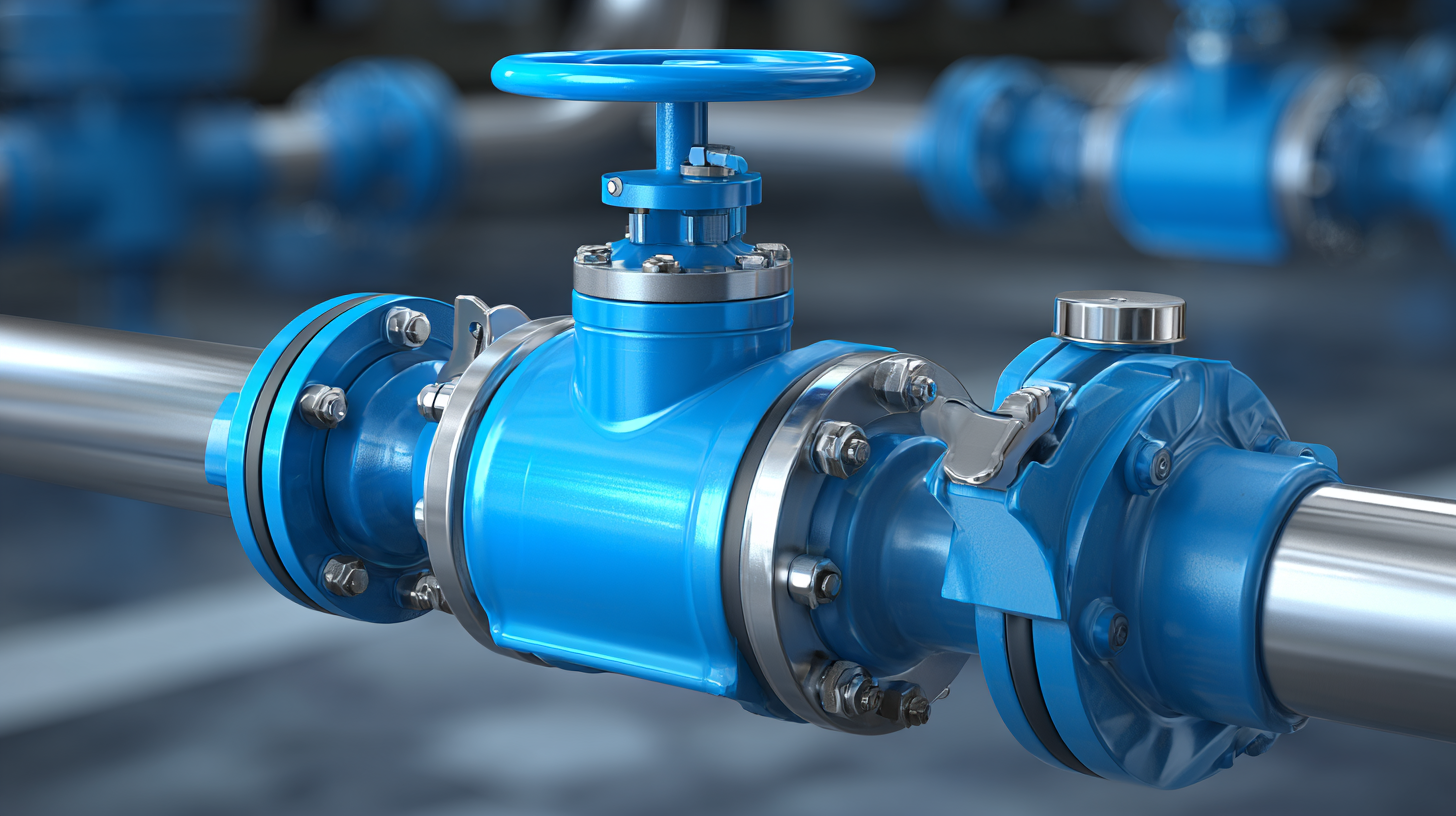

In industrial systems, the prevention of backflow is crucial for maintaining operational efficiency and safeguarding equipment. One of the key components that play a significant role in this preventive measure is the Non Return Valve. This valve functions by allowing fluid to flow in one direction while effectively blocking reverse flow, thus mitigating potential damage and contamination within the system. Understanding the essential role of Non Return Valves not only enhances system reliability but also contributes to the safety of industrial processes.

In this guide, we will explore the various types of Non Return Valves, their applications across different industries, and best practices for their installation and maintenance. By delving into these aspects, we aim to equip professionals with the knowledge needed to implement Non Return Valves effectively, ensuring robust protection against backflow and optimizing overall system performance.

Understanding Non Return Valves: Functionality and Importance in Industrial Systems

Non-return valves, also known as check valves, play a pivotal role in industrial systems by preventing backflow, which can lead to equipment damage and operational inefficiencies. According to a report by the Global Non-Return Valve Market, the demand for these valves is expected to grow at a CAGR of 5.2% from 2022 to 2030, driven by the expansion of industries like oil and gas, water treatment, and chemical manufacturing. These valves ensure that fluids flow in one direction, maintaining the integrity of systems and safeguarding against contamination and pressure fluctuations.

In addition to their primary function, non-return valves contribute to energy efficiency. The American Society of Mechanical Engineers (ASME) emphasizes that improper flow direction can lead to energy losses of up to 30% in fluid systems. By installing non-return valves, industrial facilities can enhance operational stability, reduce maintenance costs, and extend the lifespan of pumps and piping systems.

**Tips:** Ensure the correct sizing of non-return valves to match the specifications of your system. Regularly inspect and maintain these valves to prevent wear and tear, which can compromise their effectiveness. Consider the material of the valve based on the type of fluid, as this can significantly impact performance and durability.

The Essential Role of Non Return Valves in Preventing Backflow in Industrial Systems

| Dimension | Description | Importance |

|---|---|---|

| Fluid Type | Liquids and gases used in various processes | Choosing the right fluid type is crucial for valve selection |

| Installation Location | Pipelines, pumps, and tanks throughout the system | Strategic placement minimizes risk of backflow |

| Size | Varies based on system requirements | Correct sizing ensures efficiency and prevents leaks |

| Material | Metal, plastic, or rubber depending on application | Material choice affects durability and resistance to corrosion |

| Pressure Rating | Ranges from low to high pressure applications | Selecting the appropriate rating prevents valve failure |

| Maintenance Needs | Regular inspections and servicing guidelines | Proper maintenance extends the lifespan of valves |

Types of Non Return Valves: Selecting the Right One for Your Application

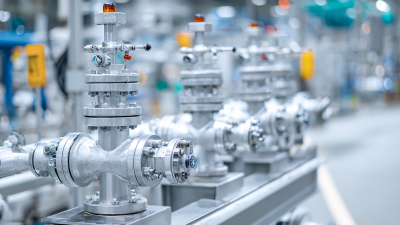

When selecting non-return valves for industrial applications, it is crucial to understand the various types available and their specific functions. Non-return valves, also known as check valves, are designed to allow fluid to flow in one direction while preventing backflow. This is essential in maintaining pressure and ensuring the integrity of the entire system. The major types include swing check valves, diaphragm check valves, and ball check valves, each offering distinct advantages depending on the application.

Key criteria for selecting the right type of non-return valve include the fluid’s viscosity, temperature, and pressure conditions. Additionally, the installation environment must be considered, as factors like space constraints and accessibility for maintenance can dictate the choice of valve.

VAMCOSA provides tailored valve solutions that enhance safety and efficiency in challenging industrial settings, facilitating optimal performance and risk reduction in compressed air systems and beyond. By understanding the specific operational requirements, industries can effectively choose non-return valves that not only prevent backflow but also improve overall process reliability.

Common Applications of Non Return Valves in Various Industrial Settings

Non-return valves, also known as check valves, play a crucial role in various industrial settings by preventing backflow, which can lead to system inefficiencies and potential damage. In water treatment facilities, for instance, the use of non-return valves ensures that treated water does not flow back into sewage systems, thereby maintaining the integrity of the clean water supply. According to a report by the Water and Wastewater Equipment Manufacturers Association (WWEMA), proper installation of non-return valves in these facilities can reduce maintenance costs by up to 20% by minimizing the risk of contamination.

In the oil and gas industry, non-return valves are essential in upstream and downstream processes to prevent backflow in pipelines and refineries. Their application helps to maintain the operational efficiency and safety of these systems. A study by the American Petroleum Institute (API) highlighted that implementing non-return valves can significantly lower the likelihood of leaks and spills, which can cost companies millions in environmental compliance and damages. Additionally, industries such as pharmaceuticals and food processing also rely on these valves to protect sensitive products, ensuring smooth operation in line with hygiene standards.

How Non Return Valves Effectively Prevent Backflow and Protect Equipment

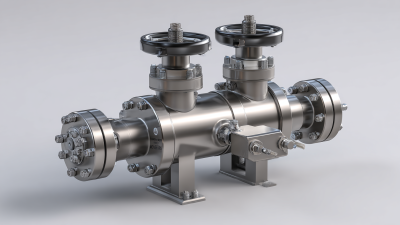

Non-return valves, also known as check valves, play a critical role in industrial systems by preventing backflow and safeguarding essential equipment. These valves function automatically, allowing fluid to flow in only one direction while blocking reverse flow when the pressure drops. This mechanism is crucial in maintaining the integrity and efficiency of piping systems. Without non-return valves, undesirable backflow can lead to contamination, equipment damage, and costly downtime.

In various industrial applications, the effectiveness of non-return valves in preventing backflow is paramount. For instance, in wastewater management, these valves ensure that treated water does not flow back into the processing system, thereby keeping the entire operation safe and efficient. In addition, in pump systems, non-return valves help maintain pressure and prevent potential hydraulic shocks that can occur if water is allowed to flow backward. The reliability of these valves not only protects equipment but also enhances the overall performance of industrial processes, making them indispensable in many sectors.

Maintenance Best Practices for Non Return Valves in Industrial Systems

Non-return valves, also known as check valves, play a crucial role in preventing backflow in industrial systems, ensuring fluid flow operates efficiently and safely. Regular maintenance of these valves is essential to their longevity and functionality. According to a report by the Hydraulic Institute, nearly 20% of industrial downtime is attributed to equipment failure, highlighting the importance of proactive maintenance practices. By focusing on the upkeep of non-return valves, industries can significantly reduce unexpected interruptions in their operations.

One key maintenance practice is to conduct periodic inspections of non-return valves to check for wear and tear. Look for signs of corrosion or sediment buildup, which can hinder the valve's performance. Additionally, implementing a routine lubrication schedule can help ensure that the valve operates smoothly.

Tips: Ensure that your inspection process includes a functional check under normal operational conditions to confirm that the valve opens and closes properly. Furthermore, consider using advanced monitoring technology that can alert you to potential issues before they escalate, improving overall system reliability and efficiency. Prioritizing these practices can lead to a reduction in maintenance costs, as reported by the American Society of Mechanical Engineers, who noted that planned maintenance can cut total operational costs by 10-15%.

Related Posts

-

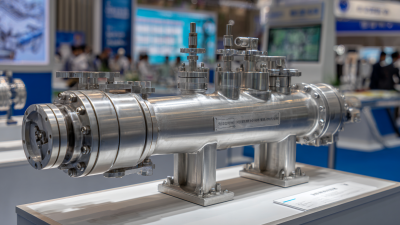

Exploring Market Opportunities for Non Return Valves at the Successful 137th Canton Fair

-

Challenges with Using Best Non Return Valves in Industrial Applications

-

Understanding Global Industry Standards for Best Cryogenic Valves in Modern Applications

-

How to Choose the Best Wafer Check Valve for Your Industrial Needs

-

The Future of Advanced Safety Relief Valve Technology

-

Exploring the Future of Pressure Valve Innovations at the 138th Canton Fair 2025 in China