Revolutionize Your Workshop with Innovative Quick Connect Air Fittings Solutions

In the evolving landscape of industrial technology, the integration of innovative solutions is paramount for enhancing operational efficiency and productivity.

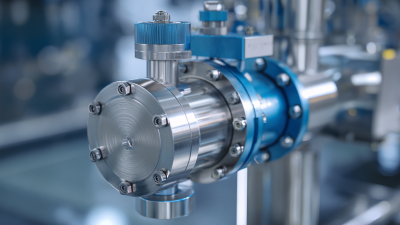

Quick Connect Air Fittings have emerged as a pivotal component in modern workshops, facilitating seamless and rapid air connections.

According to a recent report by the Pneumatic Tool Manufacturers Association (PTMA), the global market for air fittings is projected to grow by 6% annually, driven by increasing demand for automated processes and the need for reducing downtime in manufacturing operations.

These fittings not only streamline workflows but also minimize the risk of air leaks, which can significantly impact performance and safety.

As businesses strive to revolutionize their workshop environments, adopting Quick Connect Air Fittings solutions is essential for staying competitive and ensuring a high level of operational excellence.

Quick Connect Air Fittings have emerged as a pivotal component in modern workshops, facilitating seamless and rapid air connections.

According to a recent report by the Pneumatic Tool Manufacturers Association (PTMA), the global market for air fittings is projected to grow by 6% annually, driven by increasing demand for automated processes and the need for reducing downtime in manufacturing operations.

These fittings not only streamline workflows but also minimize the risk of air leaks, which can significantly impact performance and safety.

As businesses strive to revolutionize their workshop environments, adopting Quick Connect Air Fittings solutions is essential for staying competitive and ensuring a high level of operational excellence.

Understanding the Basics of Quick Connect Air Fittings for Your Workshop

Quick connect air fittings are essential components in any workshop that utilizes pneumatic tools. These fittings allow for rapid connection and disconnection of air hoses, streamlining workflow and increasing efficiency. According to a report by the Pneumatic Tool Manufacturers Association (PTMA), the global market for pneumatic tools is projected to reach USD 25 billion by 2024, reflecting the growing reliance on compressed air systems in industrial environments. Understanding the basics of these fittings can significantly enhance the performance of pneumatic setups.

The two primary materials used for quick connect fittings are brass and polymer, each offering unique advantages. Brass fittings are known for their durability and long-term performance under high pressure, while polymer fittings are lightweight and corrosion-resistant, making them ideal for less demanding applications. The proper selection and installation of these fittings can reduce air leaks by up to 30%, as highlighted in a study by the Compressed Air and Gas Institute (CAGI). With the right quick connect solutions, workshops can not only improve their operational efficiency but also maintain the integrity of their pneumatic systems over time.

Choosing the Right Quick Connect Air Fittings for Different Applications

Choosing the right quick connect air fittings is crucial for optimizing performance and efficiency in various workshop applications. According to a report by MarketsandMarkets, the global market for quick connect fittings is projected to reach $5.9 billion by 2025, growing at a CAGR of 6.1%. This growth emphasizes the increasing reliance on pneumatic systems across industries such as automotive, manufacturing, and construction, highlighting the importance of selecting the appropriate fittings.

Different applications require specific types of quick connect fittings to ensure seamless operation. For example, in high-demand environments like automotive assembly lines, selecting fittings that offer a high flow rate and robust sealing capabilities can significantly enhance productivity. Conversely, for applications involving lighter air tools, fittings made of lightweight materials may provide sufficient performance without the added bulk. Data from the National Fluid Power Association suggests that a well-chosen fitting can reduce airflow turbulence by up to 20%, positively impacting tool efficiency and energy consumption. Thus, understanding the unique demands of your workshop's applications is key to making informed decisions on quick connect air fittings.

Step-by-Step Guide to Installing Quick Connect Air Fittings

Installing quick connect air fittings can significantly enhance the efficiency of your workshop operations. According to a recent industry report by the Pneumatic Tools Association, nearly 75% of workshops using quick connect systems reported a decrease in setup time, allowing for more productive work hours.

Installing quick connect air fittings can significantly enhance the efficiency of your workshop operations. According to a recent industry report by the Pneumatic Tools Association, nearly 75% of workshops using quick connect systems reported a decrease in setup time, allowing for more productive work hours.

Tip: Always use connectors that are designed for your specific air tools to prevent leaks and inefficiencies.

Once you have your fittings, follow a systematic approach for installation. Begin by shutting off the air supply and releasing any pressure. Carefully clean the threads on both the fittings and the hoses to prevent debris from compromising the seal. Applying a suitable thread sealant can enhance the connection's integrity, reducing downtime caused by air leaks.

Tip: Regular maintenance and inspection of your fittings can prevent unexpected disruptions in your workflow, contributing to a more streamlined operation.

By integrating these practices, you can ensure a reliable and efficient workshop environment.

Maintenance Tips to Extend the Life of Your Quick Connect Air Fittings

To extend the life of your quick connect air fittings, regular maintenance is essential. First and foremost, ensure that all fittings are kept clean and free from debris. Dirt and dust can accumulate in the couplings, leading to reduced performance and potential damage. A simple wipe with a clean cloth after each use can go a long way in preserving the integrity of the fittings. Additionally, using compressed air to blow out any particles trapped in the fittings can help maintain optimal airflow and prevent wear over time.

Another crucial aspect of maintenance is checking for signs of wear and tear. Regularly inspect the fittings for cracks, leaks, or any signs of corrosion. If you notice any issues, it's best to address them promptly by replacing the damaged components. Furthermore, lubricating the fittings with suitable oil can help reduce friction during connection and disconnection, thus prolonging their lifespan. Implementing these simple maintenance tips will ensure that your quick connect air fittings remain functional and reliable, allowing you to work efficiently in your workshop.

Innovative Applications of Quick Connect Air Fittings in Modern Workshops

In modern workshops, efficiency and adaptability are paramount, making innovative applications of quick connect air fittings essential for enhancing productivity. These fittings allow for rapid connection and disconnection of air hoses and tools, significantly reducing downtime and streamlining workflows. By facilitating seamless transitions between different tools and equipment, workers can focus more on tasks rather than spending time managing connections, leading to increased operational efficiency.

Additionally, the versatility of quick connect air fittings supports a wide range of applications, from woodworking to automotive repair. This flexibility enables workshops to accommodate diverse projects and requirements without the need for extensive modifications to existing systems. Moreover, by incorporating ergonomic designs, these fittings enhance user comfort and safety, reducing the risk of injury and improving overall job satisfaction. As modern workshops continue to evolve, the integration of innovative quick connect solutions will play a crucial role in shaping a more efficient and productive working environment.

Related Posts

-

A Comprehensive Comparison of Quick Couplings for Optimal Performance

-

10 Best Practices for Choosing Your Vacuum Relief Valve

-

Transform Your Connections with Trusted Quality Quick Connect Hose Fittings Made in China

-

How to Choose the Best Wafer Check Valve for Your Industrial Needs

-

How to Choose the Right Swing Check Valve for Your Piping System Needs

-

How to Effectively Choose the Right Pressure Relief Valve for Your Applications