Top 10 Rubber Pump Impeller Types You Should Know?

In the world of industrial pumping, the selection of the right Rubber Pump Impeller is crucial. Recent industry studies indicate that over 30% of pump failures are linked to impeller inefficiencies. These failures often lead to significant downtime and increased maintenance costs, making the choice of material and design essential.

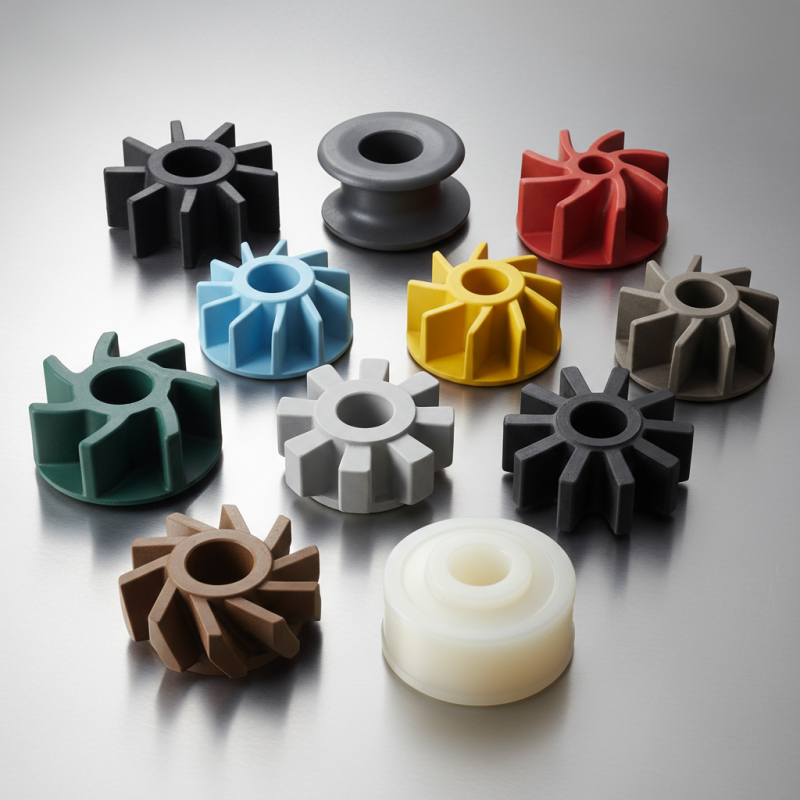

Rubber Pump Impellers come in various shapes and configurations. Each type serves different applications. Some are designed for high abrasion environments, while others excel in chemical resistance. Selecting the most suitable impeller can drastically improve operational efficiency. Yet, many users underestimate the impact of this choice. It’s vital to consider both the working conditions and the specific properties of materials.

Understanding the top 10 Rubber Pump Impeller types can enhance performance and reliability. The nuances of each type may seem minor, but they can cause substantial differences in pump behavior. By acknowledging these details, industry professionals can better navigate the complexities of rubber impeller selection and ultimately drive down operational costs.

Overview of Rubber Pump Impellers

Rubber pump impellers play a crucial role in various industrial applications. They are designed to efficiently transfer fluid while minimizing wear and tear. The material itself provides flexibility and resistance against abrasives, which is essential in many environments. According to a recent industry report, around 35% of pump failures are attributed to impeller wear. This highlights the importance of selecting the right type of rubber impeller.

Various designs of rubber impellers exist, each suited for specific applications. The most common types include closed, semi-open, and open impellers. Closed impellers are efficient for high-pressure systems. Semi-open types handle solids better, while open impellers are often used in wastewater management. It's essential to match the impeller type with the application needs to avoid inefficient operation and increased maintenance costs.

Despite the advantages, there are challenges. Rubber impellers may struggle with extreme temperatures, leading to deformation. Regular monitoring is necessary to identify wear patterns. Furthermore, the choice of rubber grade can significantly impact performance. Selecting the wrong material may result in reduced efficiency and higher replacement rates. These factors all point to critical considerations in the effective use of rubber pump impellers.

Common Materials Used in Rubber Pump Impellers

Rubber pump impellers play a crucial role in various industries. They are designed to enhance fluid flow while minimizing wear and tear. The performance of these impellers heavily depends on the materials used in their construction. Commonly, compounds like natural rubber, neoprene, and nitrile rubber are utilized.

Natural rubber offers excellent elasticity and resistance to wear. However, it may not perform well in extreme temperatures. On the other hand, neoprene is more versatile. It withstands oil and chemicals better than natural rubber. Nitrile rubber provides exceptional durability against abrasion, but it can be costly.

Tip: Choose the right material based on your specific application. Evaluating the operating conditions can help you maximize efficiency and lifespan.

Inconsistent material quality can lead to unpredictable results. Not every rubber compound is suitable for every application. This inconsistency might cause inefficiencies, including increased energy consumption or pump failure. It's essential to consider various factors, such as pH levels and temperature ranges, when selecting your impeller material.

Tip: Regularly inspect your pump impellers for signs of wear. This practice can help prevent costly replacements and downtime.

Types of Rubber Pump Impellers and Their Applications

Rubber pump impellers play a crucial role in various industries. They are widely used in water treatment plants, chemical processing, and food production. Their flexibility and resistance to abrasion make them ideal for handling different liquids. Choosing the correct type of impeller is essential for efficiency.

There are several types of rubber pump impellers, each with unique applications. Open impellers are popular in applications with solid particles. They allow for better fluid flow but can wear out quickly. Closed impellers provide higher efficiency but are prone to clogging. Vortex impellers offer great handling for slurries and viscous fluids, but their performance can be inconsistent.

Some users overlook the importance of regular maintenance. Frequent inspections can prevent sudden failures. Neglecting this can lead to significant downtime. Additionally, understanding the specific needs of your operation is vital. Not every impeller is suited for all tasks. Finding the right fit will improve performance.

Top 10 Rubber Pump Impeller Types and Their Applications

Factors Affecting Performance of Rubber Pump Impellers

Rubber pump impellers are vital for performance. They move fluids efficiently, but several factors can impact their effectiveness. Material composition is key. Different rubber compounds offer various levels of durability and flexibility. Choosing the right material matters for the intended application. If the wrong material is used, it can lead to quick wear and tear.

Another important factor is design. The shape and size of the impeller influence flow rates. A poorly designed impeller may cause cavitation. This issue results in decreased efficiency and can even damage the pump. Regular maintenance helps monitor wear, but sometimes neglect leads to unexpected failures.

Operating conditions also play a role. Temperature and viscosity affect performance. High temperatures can degrade rubber faster. If the fluid is too viscous, that can hinder movement. It's crucial to find the right balance. Adjustments may be needed based on the specific environment where the pump operates. Understanding these factors helps in selecting the best impeller type for increasing longevity and performance.

Maintenance Tips for Rubber Pump Impellers

Rubber pump impellers play a critical role in fluid movement. Proper maintenance extends their lifespan and ensures efficiency. Regular inspections are essential. Check for wear, cracks, or any signs of damage. Small issues can lead to bigger problems later.

Cleaning the impellers frequently helps prevent build-up of debris. Rinse them with fresh water after use. This simple step can avoid performance degradation. Additionally, consider the operating environment. Dusty or abrasive conditions can wear out rubber quickly. Regularly replace impellers that show excessive wear.

Lubrication can be beneficial but must be done correctly. Too much can attract dirt and grime. Too little may cause friction. Finding the right balance is vital. Keeping an eye on performance is also recommended. Notice any unusual vibrations or changes in flow. These can be signs that something is amiss.

Top 10 Rubber Pump Impeller Types You Should Know

| Impeller Type | Material Composition | Applications | Advantages | Maintenance Tips |

|---|---|---|---|---|

| Standard Rubber Impeller | Natural or Synthetic Rubber | General Water Transfer | Cost-effective, Good wear resistance | Regular inspections for wear |

| Nitrile Impeller | Nitrile Rubber | Oil and Fuel Transfer | Chemical resistance, durable | Clean surfaces to prevent corrosion |

| EPDM Impeller | Ethylene Propylene Diene Monomer | Water Applications with UV Exposure | Excellent temperature resistance | Store in a cool, dry place |

| Neoprene Impeller | Chloroprene Rubber | Chemical Processes | Good abrasion resistance | Check for cracks regularly |

| Silicone Impeller | Silicone Rubber | High Temperature Applications | Flexible, highly resilient | Avoid exposing to sharp objects |

| Viton Impeller | Fluoroelastomer | Extreme Chemical Applications | Outstanding resistance to chemicals | Inspect for chemical deterioration |

| Polyurethane Impeller | Polyurethane Compounds | Heavy Duty Applications | High wear resistance | Regularly clean to avoid sludge buildup |

| Polypropylene Impeller | Polypropylene Material | Wastewater Applications | Corrosion resistant | Monitor for signs of wear |

| Rubber Coated Metal Impeller | Metal Core with Rubber Coating | High Mechanical Stress Applications | Combines durability with flexibility | Inspect for rubber degradation |

| Fabric Reinforced Rubber Impeller | Rubber with Fabric Layer | Heavy Liquid Applications | Enhanced strength, reduced deformation | Regular checks for fabric exposure |